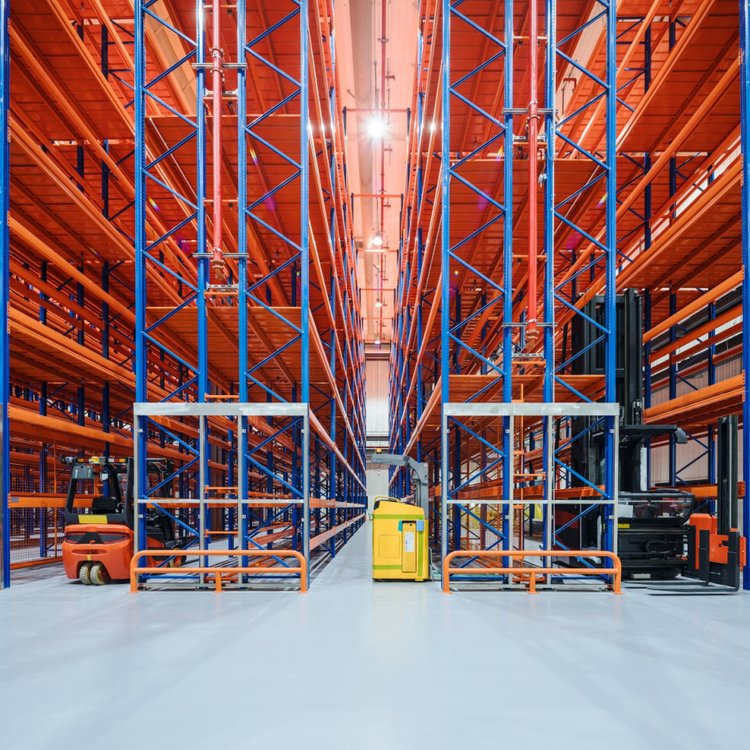

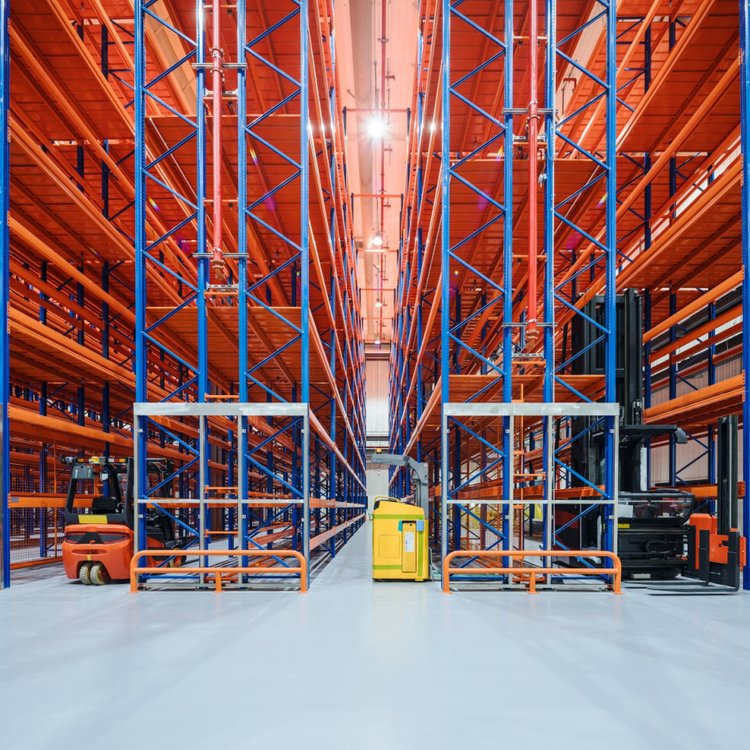

Hey folks in logistics, warehousing, and operations! Let’s cut to the chase: you’re under pressure. Space is expensive, labor costs keep climbing, and customers want everything yesterday. If your warehouse feels like it’s bursting at the seams or your forklifts are constantly stuck in traffic jams, it’s time for a serious conversation about Narrow Aisle Racking (NAR). This isn't just another storage system; it's a strategic powerhouse for boosting efficiency and your bottom line. Forget just storing stuff; let's talk about optimizing your entire flow.

The Warehouse Squeeze: Why Traditional Systems Fall Short

Picture this: wide aisles designed for old-school, clunky forklifts. Pallet locations stacked high, but only partially filled because reaching the top tiers safely is a nightmare. Forklifts constantly turning wide corners, wasting precious minutes (which add up to hours and days) on just maneuvering. Every square foot taken up by an aisle is space not generating revenue through stored product. This is the reality for many warehouses stuck with conventional wide-aisle racking.

The consequences? Brutal:

- Wasted Real Estate: Up to 50% or more of your warehouse floor space might be dedicated just to aisles. That’s prime real estate you’re paying for, heated, cooled, and lit, that isn’t holding inventory.

- Sky-High Labor Costs: Forklifts spending more time driving than lifting. Operators traveling longer distances between picks and drops. All that fuel and labor time adds up fast.

- Throughput Bottlenecks: Congestion in aisles slows everything down. Receiving gets backed up, orders take longer to pick, and shipping misses deadlines.

- Safety Headaches: Wider aisles can sometimes lead to complacency. Tight maneuvers with standard trucks in confined spaces? Recipe for damaged product and racking.

Simply put, traditional setups often mean you're paying more to store less and move it slower. Not exactly a winning formula.

Enter the Game-Changer: What is Narrow Aisle Racking?

So, what’s the solution? Narrow Aisle Racking is precisely what it sounds like: a storage system specifically engineered to function in significantly narrower aisles compared to conventional setups. We're talking aisles typically ranging from 6 to 8 feet wide, sometimes even less with specialized equipment – compared to the 12+ feet often needed for standard counterbalance forklifts.

But here’s the magic: it’s not just the racking itself. It’s the integrated system. Narrow Aisle Racking systems are designed to work hand-in-glove with specialized material handling equipment (MHE):

- Narrow Aisle Forklifts (Reach Trucks): These are the workhorses. They have a tighter turning radius, operate in a "side-stance" (operator faces the racking), and feature extendable forks to access pallets deep within the rack bay. They’re built for precision in tight spaces.

- Very Narrow Aisle (VNA) Equipment: Taking it a step further, VNA systems operate in aisles as narrow as 5-6 feet. This often involves:Turret Trucks: Where the operator compartment lifts with the forks, allowing for high-level order picking directly from the pallet.Order Pickers: Designed for manual picking at various levels within the Narrow Aisle Racking structure.Guided Systems: Wire or rail guidance ensures millimeter precision, maximizing safety and speed in those ultra-tight spaces.

The racking itself? It’s typically robust, high-quality structural or roll-formed steel racking designed for greater heights (often leveraging your building’s clear height potential) and the specific demands of the narrower operating environment. Safety features like column protectors and rack guards become even more critical.

The Efficiency Payoff: Why NAR Delivers Big Time

Okay, the setup sounds cool, but what’s the real impact? Why is Narrow Aisle Racking such an efficiency powerhouse?

- Massive Space Savings (Density is King!): This is the headline benefit. Reducing aisle widths by 30-50% translates directly into huge gains in storage capacity within the same building footprint. Imagine storing 30-50% more pallets without adding a single square foot of floor space. That means delaying or even eliminating the need for costly expansion or relocation. Your existing warehouse suddenly becomes way more valuable.

- Labor Costs Take a Nosedive: Less driving distance between picks equals more picks per hour. Operators spend significantly more time on productive lifting and placing, not traversing vast expanses of concrete. Fewer trucks might be needed to handle the same volume. Faster cycle times mean quicker order fulfillment. This directly slashes labor costs and boosts throughput.

- Accuracy Gets a Boost: Operating in a more structured, confined environment with specialized equipment often leads to fewer handling errors. Operators are focused on the task directly in front of them within the Narrow Aisle Racking system. Reduced travel also means less opportunity for pallets to shift or get damaged in transit.

- Inventory Visibility Improves: Higher density often means better utilization of vertical space. While you go higher, modern Narrow Aisle Racking setups integrate seamlessly with warehouse management systems (WMS). This makes inventory tracking and location management more precise, reducing search times and stockouts.

- Energy Costs Dip (Slightly): Less floor space to heat, cool, and light? That translates into some energy savings. While not the primary driver, it’s a nice bonus on top of the major wins.

Think of it as doing way more with what you already have – your building and your people. It’s about optimizing the core of your operation.

Making the Switch: Key Considerations for NAR Success

Jumping into Narrow Aisle Racking isn't just buying some new racks and trucks. It requires careful planning and investment. Here’s what you need to nail:

- Building Assessment is Job #1: How high is your clear ceiling height? What’s the floor condition like (flatness is CRITICAL for VNA)? Are your columns strategically placed? Your building’s specs dictate the maximum potential of your Narrow Aisle Racking system. You absolutely need an expert site survey.

- Equipment Selection is Paramount: This isn't DIY territory. Partner with reputable Narrow Aisle Racking and MHE specialists. The choice between standard narrow aisle reach trucks and guided VNA systems depends entirely on your required density, throughput speeds, budget, and building constraints. Don’t skimp here – the right equipment is the engine of your efficiency.

- Operator Training is Non-Negotiable: Operating safely and efficiently in tight spaces requires skill. Comprehensive, certified training for operators on the specific equipment they’ll use is mandatory. This is a major safety and ROI factor.

- Integrate Your WMS: To truly unlock the potential, your Warehouse Management System needs to be optimized for the new layout and picking strategies enabled by the Narrow Aisle Racking system. Slotting optimization becomes even more powerful.

- Safety First, Always: Narrower aisles demand heightened safety protocols. This includes robust rack inspection programs, clear pedestrian walkways completely segregated from operating aisles, speed limits, high-visibility markings, and potentially enhanced lighting within the aisles. The guidance systems in VNA significantly enhance safety.

Crunching the Numbers: The ROI of Going Narrow

Let's talk dollars and cents. Yes, implementing a Narrow Aisle Racking system involves a significant upfront investment – the racking itself, new specialized MHE, potentially building modifications (like floor leveling), and training.

However, the payback period is often surprisingly attractive, typically ranging from 2 to 5 years. How?

- Deferred/Canceled Expansion: Avoiding the astronomical costs of building a new warehouse or leasing additional space is a massive financial win.

- Labor Savings: More pallets moved per hour per operator directly reduces payroll costs and overtime. You might even reduce your fleet size.

- Increased Throughput: Faster order fulfillment means happier customers, potential for more business, and reduced penalty costs.

- Reduced Product Damage: Fewer mishaps mean less waste and replacement costs.

- Better Space Utilization: You're monetizing previously wasted space within your existing footprint.

Think of it as a capital investment that generates continuous operational savings and capacity gains. It’s an investment in efficiency that pays dividends for years.

Is Narrow Aisle Racking Right For YOUR Operation?

Narrow Aisle Racking isn't a magic bullet for every single warehouse, but it’s incredibly powerful for many. It shines brightest when:

- You’re seriously space-constrained ("We have nowhere else to put this stuff!").

- Real estate costs (buying or leasing) are high.

- Labor costs are a major pain point.

- You need significantly higher throughput.

- Your product profile and SKU count suit high-density storage (e.g., many SKUs with medium velocity).

- You have sufficient clear ceiling height (ideally 25 feet or more).

- You're ready to invest in the right equipment and training.

If you’re constantly battling for space, drowning in labor costs, or struggling to keep up with order volume, Narrow Aisle Racking deserves your serious attention. It’s a proven strategy for turning warehouse constraints into competitive advantages.

The Bottom Line: Work Smarter, Not Harder (or Bigger)

In today's hyper-competitive market, warehouse efficiency isn't just nice to have; it's survival. Narrow Aisle Racking represents one of the most impactful ways to fundamentally transform your operation without the back-breaking cost of expansion. It’s about leveraging smarter design, specialized equipment, and optimized workflows to squeeze maximum value out of every square foot and every labor hour.

Stop driving farther than you need to. Stop paying for empty air above your racks or wasted concrete between them. Embrace the power of density. Embrace the focus of the narrow aisle.

Want to increase efficiency? Seriously, try Narrow Aisle Racking. It might just be the smartest squeeze you ever put on your warehouse. Get a qualified consultant in, assess your specific needs, run the numbers, and see how much more you can do right where you stand. The efficiency revolution could be just a narrow aisle away.

Wechat

Wechat

Whatsapp

Whatsapp