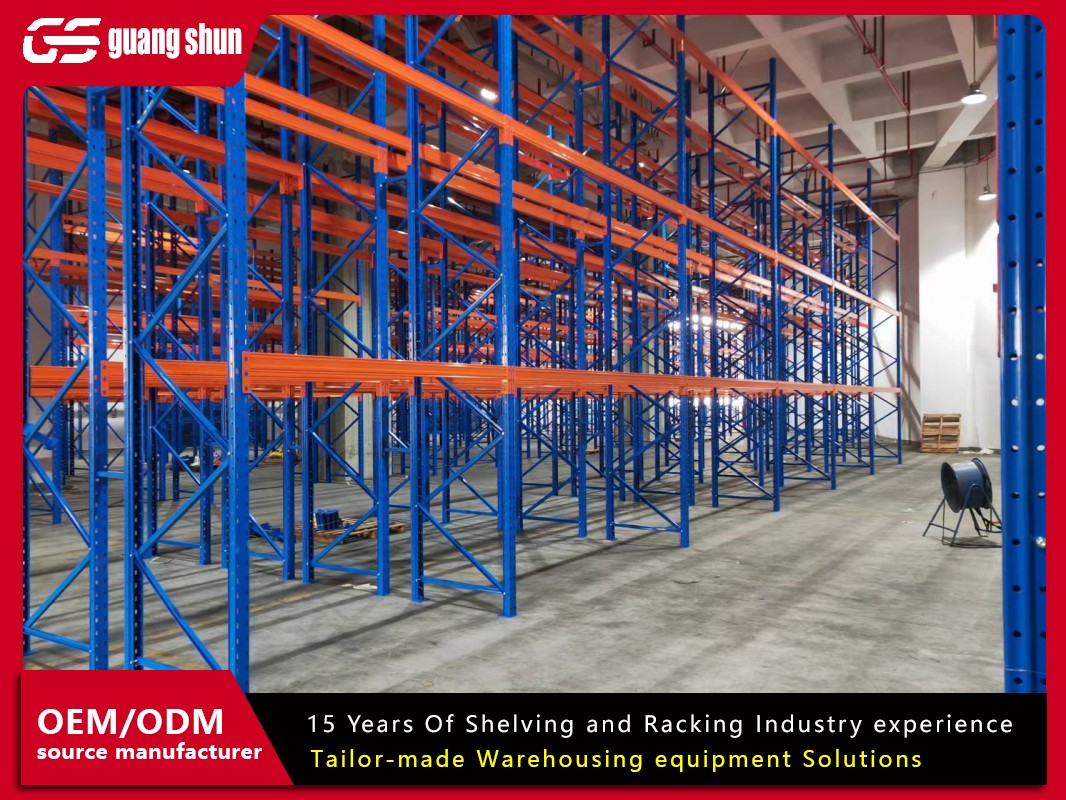

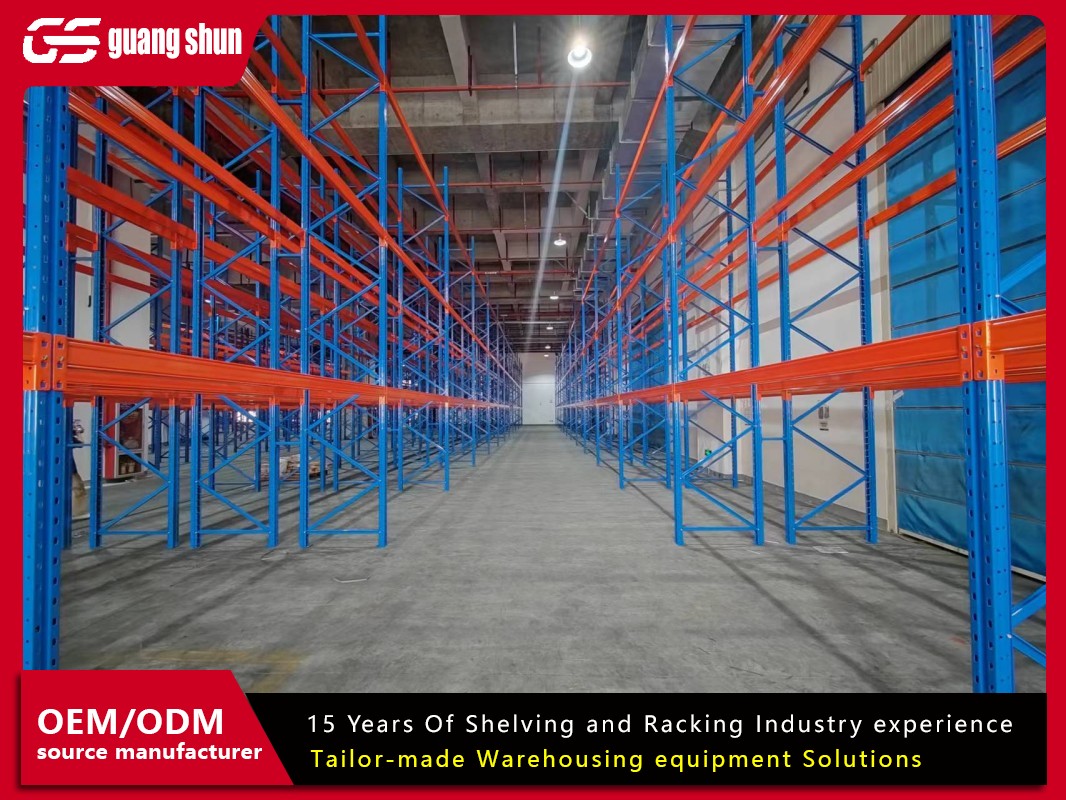

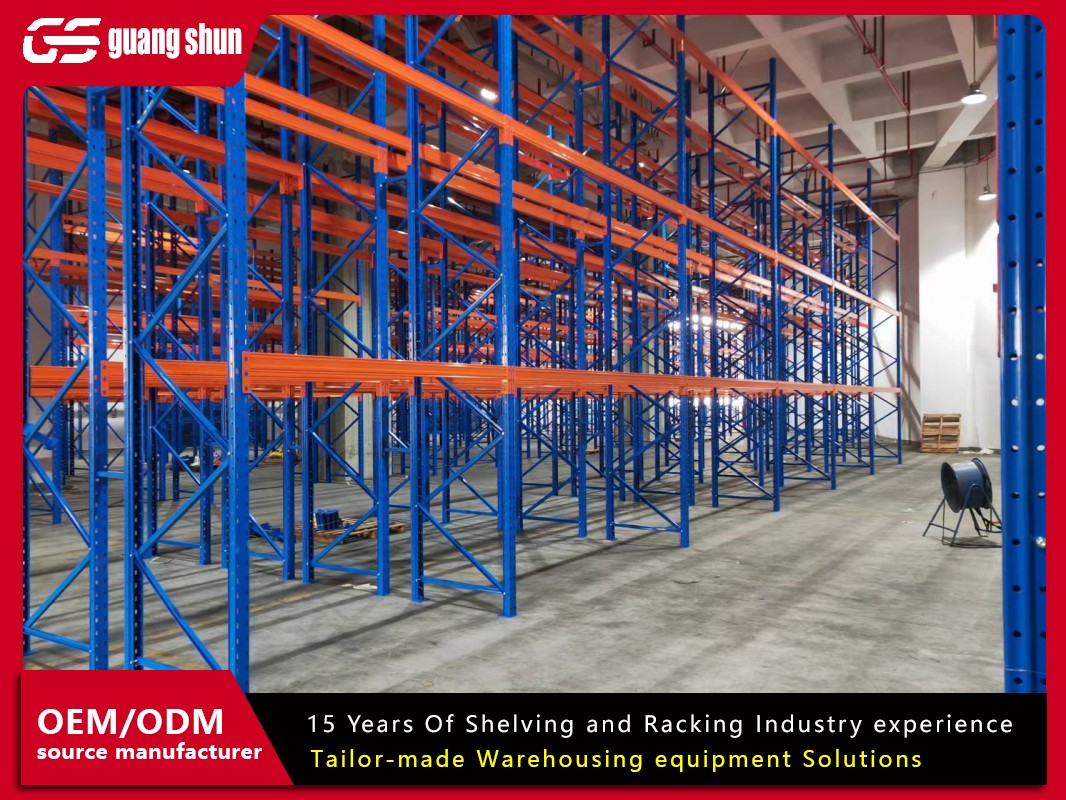

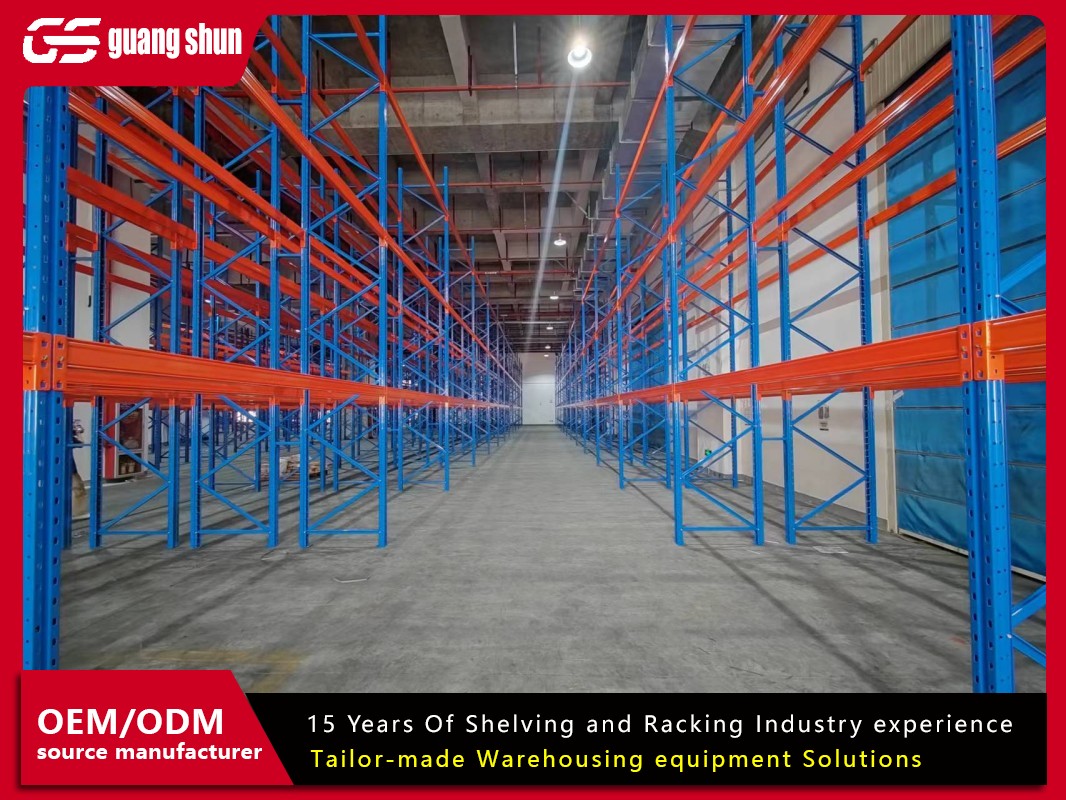

Double deep pallet racking also call the Double-depth racking is designed with two rows of shelves, which can store four pallets at the same time. It is this double-row storage design that reduces the number of aisles in the same space by half, thus improving inventory capacity.

1. Space Saving: Double deep pallet racking allows for full utilization of warehouse space, allowing racks to be arranged against walls or in corners, eliminating wasted space.

2. Improved Storage Efficiency: Goods can be loaded and unloaded in both directions, reducing operational time and space, and improving storage efficiency.

3. Wide Application: Double deep pallet racking is suitable for storing items of various sizes and shapes, especially long items such as pipes and plates.

4. Easy Operation: Double deep pallet racking is easy to operate, allowing for easy loading and unloading using a forklift.

1.The core difference between double-depth racking systems and ordinary heavy-duty pallet racking lies in storage density and access logic: double-depth racking achieves higher storage density through a double-row parallel structure, but has limited access flexibility, while ordinary pallet racking systems use single-row storage to ensure convenient access but have lower space utilization.

1.Double-deep racks store two rows of pallets, while ordinary pallet racking system store only one row. Given the same area, double-deep racks can store 1.8–2 times the capacity of single-deep racks.

2.Standard pallet racking systems support 100% picking efficiency and first-in, first-out (FIFO). Double-depth racking only offers 50% pickability and is often first-in, first-out. Double deep pallet racking requires removing pallets from the front row before loading and unloading goods from the rear row, making the process more complex.

It saves aisle space and the floor utilization rate can reach 42%. The construction cost per unit area is lower than that of automated high-bay warehouses.

Requires a dedicated forklift, resulting in high initial investment costs; low inventory turnover, making it difficult to manage multiple categories of goods

1. When installing Double deep pallet racking, first ensure the warehouse floor is level and has sufficient load-bearing capacity. Reinforce the floor if necessary.

2. During installation, strictly follow the design drawings. First, erect the columns to ensure verticality and stability, keeping tolerances within a minimal range.

3. When installing crossbeams, ensure they are securely connected to the columns. Use high-strength bolts to secure the crossbeams and conduct a secondary inspection to prevent loosening.

4. During installation, precisely adjust the spacing and height between the front and rear rows of pallets to ensure smooth access for forklifts.

5. When installing the guides and positioning system, ensure they are positioned accurately and coordinate well with the overall rack structure.

6. After installation, conduct a comprehensive quality inspection and load test to ensure the racking meets operational requirements.

Rack frame depth can be 42” or 48” deep for storage applications using standard-sized pallets. Both depths have pluses and maybe challenges depending on how you look at it. Note: If you're using odd-sized pallets, the Apex team can help you design a custom pallet rack configuration to accommodate the pallet dimensions.

| L*D*H (in) | 7.5ft*42''*16ft,8ft*42''*18ft ,9ft*42''*20ft(most common), customizable |

| Layer | 4Layer, 5Layer, 6Layer, Customizable |

| Load Capacity | 2205lb, 4410lb, 6615lb, Customizable |

| MOQ | 10 sets |

| Weight | about 255lb-372lb |

| Volume | 0.30CBM |

| Estimated Delivery Time | 0-15 days |

Double deep pallet racking also call the Double-depth racking is designed with two rows of shelves, which can store four pallets at the same time. It is this double-row storage design that reduces the number of aisles in the same space by half, thus improving inventory capacity.

1. Space Saving: Double deep pallet racking allows for full utilization of warehouse space, allowing racks to be arranged against walls or in corners, eliminating wasted space.

2. Improved Storage Efficiency: Goods can be loaded and unloaded in both directions, reducing operational time and space, and improving storage efficiency.

3. Wide Application: Double deep pallet racking is suitable for storing items of various sizes and shapes, especially long items such as pipes and plates.

4. Easy Operation: Double deep pallet racking is easy to operate, allowing for easy loading and unloading using a forklift.

1.The core difference between double-depth racking systems and ordinary heavy-duty pallet racking lies in storage density and access logic: double-depth racking achieves higher storage density through a double-row parallel structure, but has limited access flexibility, while ordinary pallet racking systems use single-row storage to ensure convenient access but have lower space utilization.

1.Double-deep racks store two rows of pallets, while ordinary pallet racking system store only one row. Given the same area, double-deep racks can store 1.8–2 times the capacity of single-deep racks.

2.Standard pallet racking systems support 100% picking efficiency and first-in, first-out (FIFO). Double-depth racking only offers 50% pickability and is often first-in, first-out. Double deep pallet racking requires removing pallets from the front row before loading and unloading goods from the rear row, making the process more complex.

It saves aisle space and the floor utilization rate can reach 42%. The construction cost per unit area is lower than that of automated high-bay warehouses.

Requires a dedicated forklift, resulting in high initial investment costs; low inventory turnover, making it difficult to manage multiple categories of goods

1. When installing Double deep pallet racking, first ensure the warehouse floor is level and has sufficient load-bearing capacity. Reinforce the floor if necessary.

2. During installation, strictly follow the design drawings. First, erect the columns to ensure verticality and stability, keeping tolerances within a minimal range.

3. When installing crossbeams, ensure they are securely connected to the columns. Use high-strength bolts to secure the crossbeams and conduct a secondary inspection to prevent loosening.

4. During installation, precisely adjust the spacing and height between the front and rear rows of pallets to ensure smooth access for forklifts.

5. When installing the guides and positioning system, ensure they are positioned accurately and coordinate well with the overall rack structure.

6. After installation, conduct a comprehensive quality inspection and load test to ensure the racking meets operational requirements.

Wechat

Wechat

Whatsapp

Whatsapp