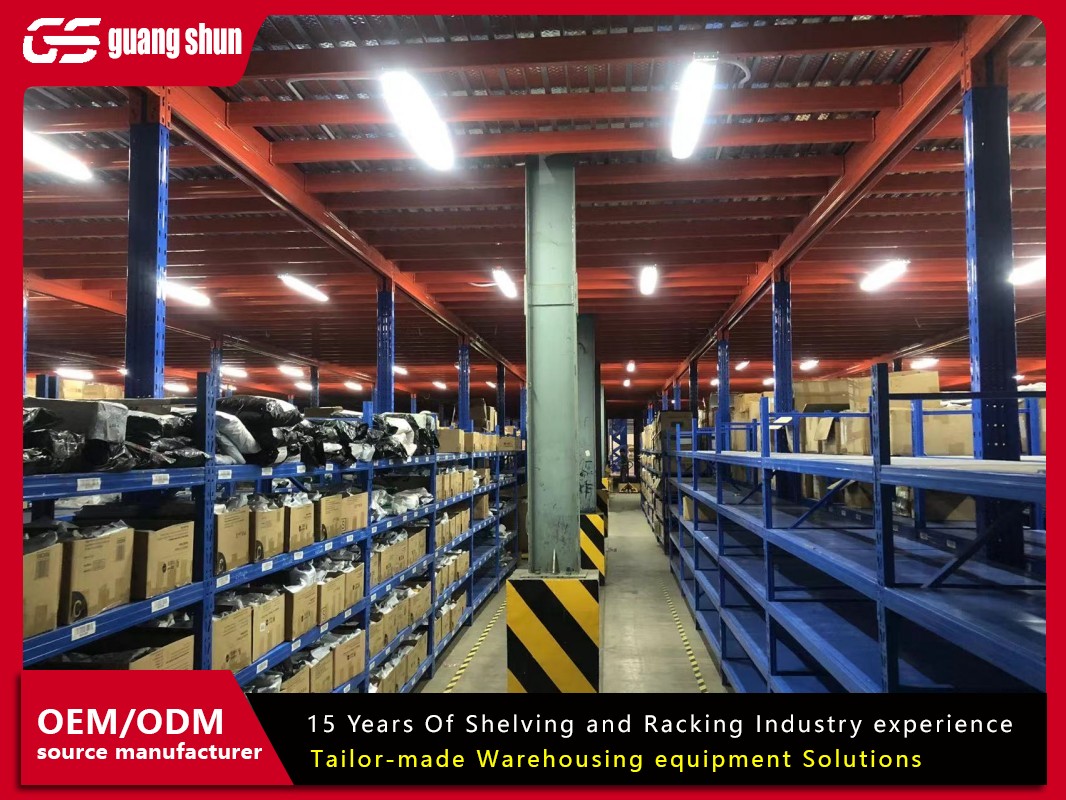

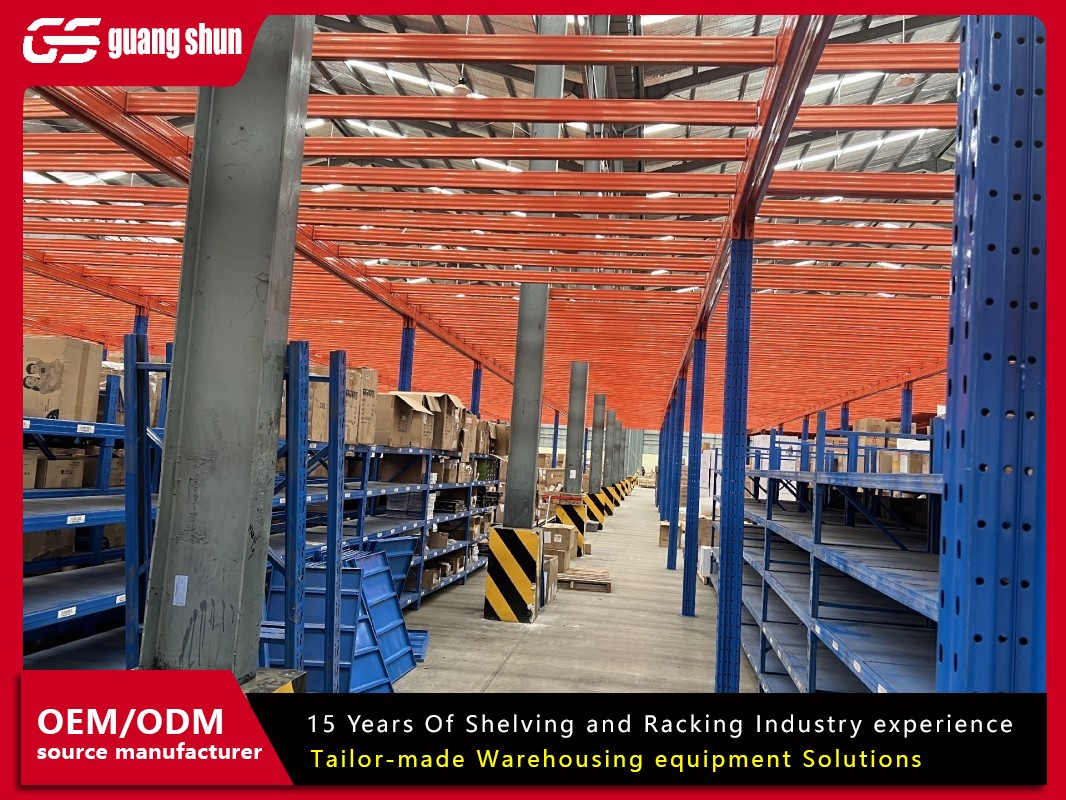

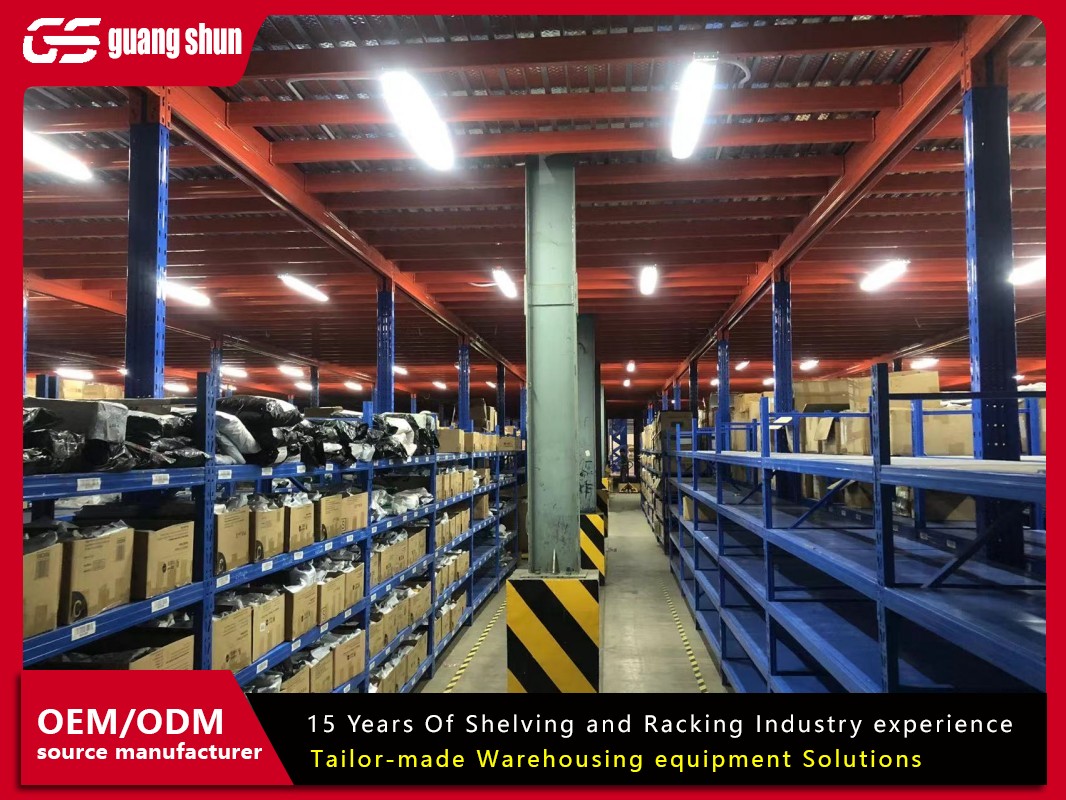

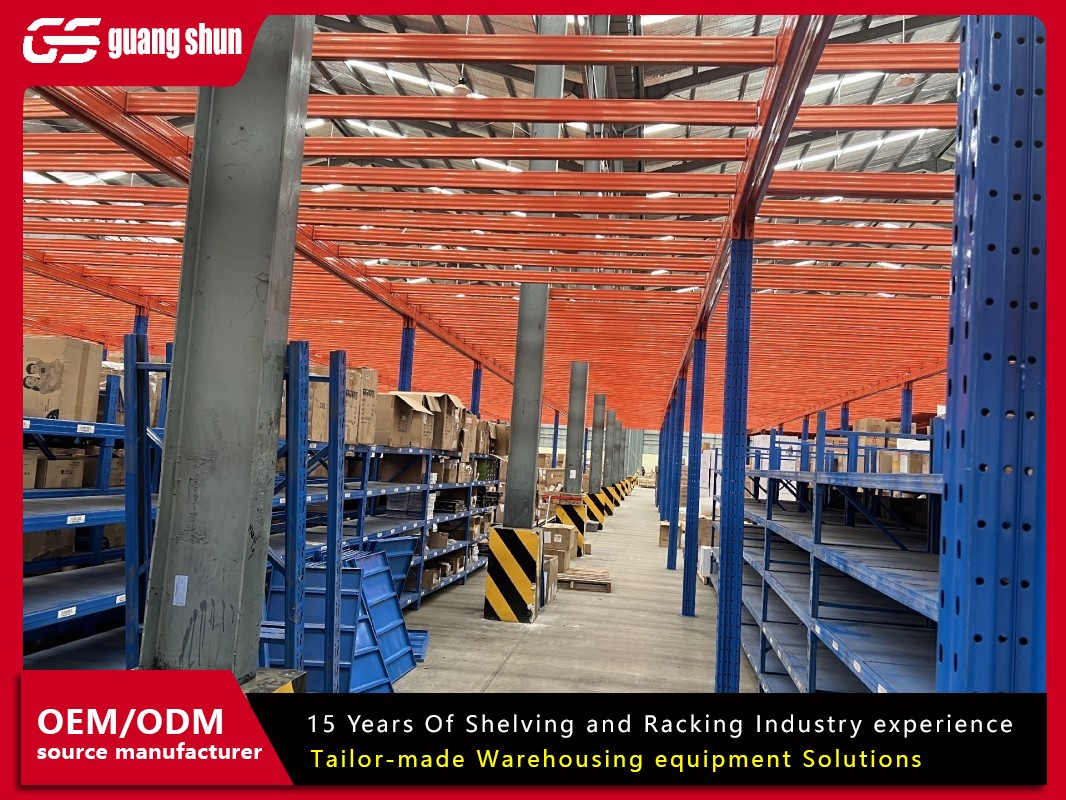

1. Mezzanine shelves is a modular structure, requiring no on-site welding, resulting in an aesthetically pleasing and elegant design. Compared to concrete or steel structures, the ground floor racking itself supports the upper floors, offering advantages such as lower costs and higher space utilization.

2. Mezzanine shelves panels are available in various styles, including flat, patterned, and perforated steel, to meet diverse requirements for fire protection, ventilation, and lighting. Forklifts, hydraulic lifts, and freight elevators can be used to transport goods up and down floors; small hand trucks are typically used for transporting goods within the same floor.

3. Mezzanine shelves typically has a load capacity of 300-1000 kg/m2. Columns are constructed from round tubes, which offer high load capacity and minimal steel consumption. Primary and secondary beams can be selected based on load requirements using H-sections, the most economical and reasonable steel structure currently available, or C-section cold-formed beams developed by Saxon, a specialized steel platform. 4. The mezzanine floor panels are made of Saxony's special C-shaped cold-formed patterned steel plates or hollow plates. They adopt a gusset plate structure and are rigidly fixed to the main and secondary beams. The entire platform structure has a strong integrity. Different floor panels can be selected according to actual needs to meet fire protection, dust protection, and small item falling protection requirements. A lighting system can also be configured under the floor as needed.

Mezzanine shelves is called shelf supported mezzanine .shelf supported mezzanine solutions can significantly improve storage space utilization and operational efficiency through optimized structural design.

A "butterfly hole + diamond hole" connection structure, combined with anti-slip corrugated steel plates, effectively enhances shelf stability. High-strength cold-rolled steel plates combined with patented truss columns enable a single-layer load capacity of up to 8 tons, addressing the load-bearing limitations of traditional racking.

The modular design allows for expansion by 2,000 square meters in three days, allowing for adjustments to floor heights and layouts based on actual needs. Comprehensive facilities, including stairs, loading ports, and lifts, accommodate various handling methods, including forklifts and freight elevators.

1100mm high guardrails and 100mm toeboards are standard, eliminating the risk of falls. Inclined roller slides increase picking efficiency by 300%, and LED lighting embedded in the shelves reduces energy consumption by 40%.

In the mezzanine racking sector, Guangshun Racking , with years of experience and experience, has a deep understanding of the needs of diverse warehousing scenarios. It offers a wide range of shelving products: lightweight mezzanine racks are light and flexible, like exquisite homes designed for small and light parts; while medium-duty shelves and heavy-duty shelves , with their sturdy construction, steadily carry heavy, bulky goods. Guangshun Racking's professional customization ensures that every inch of upward space is fully utilized, bringing unprecedented efficiency and vitality to warehouses.

An electronics company once faced a storage capacity shortage, but the introduction of Guangshun mezzanine racking quickly resolved the problem. Goods that had previously been stacked on the ground, obstructing aisles, can now be safely ascended via stairs and neatly stored in spacious "sky floors." This not only significantly increases the warehouse's available storage area, effectively alleviating inventory pressure, but also provides clear and efficient retrieval routes, truly unlocking the value of the space.

| Material | Cold-rolled Steel |

| Product size | Length: 2300 / 2500 / 2700 / 3000 / 3300 / 3600 / 3900 mm Width: 900 / 1000 / 1100 / 1200 mm Height: 2000-6500 mm |

| Thickness | column:1.5 mm, 2.0 mm |

| Load capacity | 500 kg-5000 kg per layer |

| Layers | 2-5 adjustable layers (can be custom made) |

| Color | RAL color; As per customer’s requirement |

| Surface | Electrostatic spray surface |

| Feature | Anti-rust, Corrosion-protection |

| Guarantee period | 5 years warranty |

| Remark | OEM & ODM accepted |

Mezzanine shelves are an elevated platform that creates additional storage space in a warehouse or industrial setting. They are typically supported by steel columns and can be equipped with shelving units to maximize storage capacity. Mezzanine shelves are an efficient way to increase storage space without the need for expanding the building footprint.

Mezzanine shelves typically consist of a raised platform or intermediate floor level that provides additional space for storing items, with shelving units installed on top of or underneath the platform. They work by utilizing vertical space efficiently to maximize storage capacity within a given area. The platform is usually accessed by stairs, ladders, or a ramp, allowing users to easily retrieve items stored on the shelving units. Mezzanine shelves can be customized to fit specific storage needs and can be used in various industries such as warehousing, manufacturing, and retail.

Some advantages of mezzanine shelves include:

1. Maximizing vertical space: Mezzanine shelves utilize the vertical space in a warehouse or facility, allowing for increased storage capacity without the need for additional floor space.

2. Improved organization: Mezzanine shelves provide a structured and organized storage solution, making it easier to access and manage inventory.

3. Customizable design: Mezzanine shelves can be customized to fit specific space requirements and storage needs, providing a versatile storage solution.

4. Cost-effective: Mezzanine shelves can be a cost-effective storage solution compared to expanding or relocating to a larger facility.

5. Increased efficiency: Mezzanine shelves can help improve workflow and efficiency by optimizing storage space and making inventory management more streamlined.

The purpose of mezzanine shelves is to maximize vertical storage space by adding an additional level of shelving above the existing floor space. This allows for increased storage capacity without requiring additional floor space, making it a cost-effective solution for organizing and storing inventory in warehouses, distribution centers, and retail spaces.

1. The warehouse requires a large volume of goods, a wide variety of goods, and manual retrieval.

2. The storage and logistics center urgently needs to increase storage space or maintain a certain level of storage capacity.

3. High logistics efficiency is required.

4. The warehouse requires a high clear height, with 4.2 to 6.5 meters being optimal.

The main differences between pallet racking and mezzanine shelves lie in their structure, applicable scenarios, and functions:

1. Pallet racking consists of columns, beams, and diagonal braces. Mezzanine shelves are constructed by building a platform on top of existing pallet racking , creating a double- or multi-layer structure.

2. Pallet racking is suitable for storing heavy goods, while mezzanine shelves are suitable for storing small and medium-sized light goods.

3. Pallet racking is less expensive and easier to install, while mezzanine shelves requires an additional platform, resulting in higher initial costs but significantly improving space utilization.

4. Pallet racking primarily relies on mechanical handling, allowing for 100% free picking of goods. Mezzanine shelves requires manual or hydraulic equipment for lifting and lowering, resulting in lower efficiency.

Mezzanine shelves requires adding floors to existing warehouses or storage spaces. This involves complex structures such as steel floors, stairs, and guardrails.

The design must consider multiple factors, including load-bearing capacity, span, and safety, significantly increasing material and process costs.

The mainstream material is Q235B cold-rolled steel. For higher load-bearing capacities, thicker steel or specialized materials like steel gussets are required.

Wechat

Wechat

Whatsapp

Whatsapp