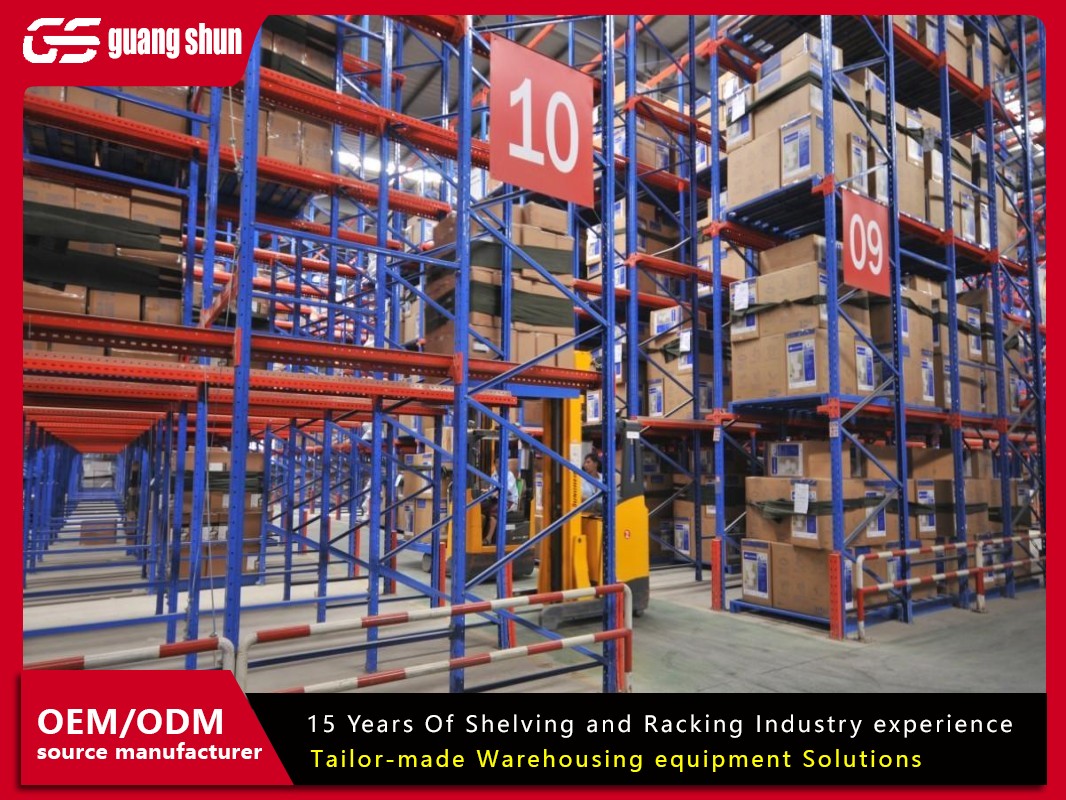

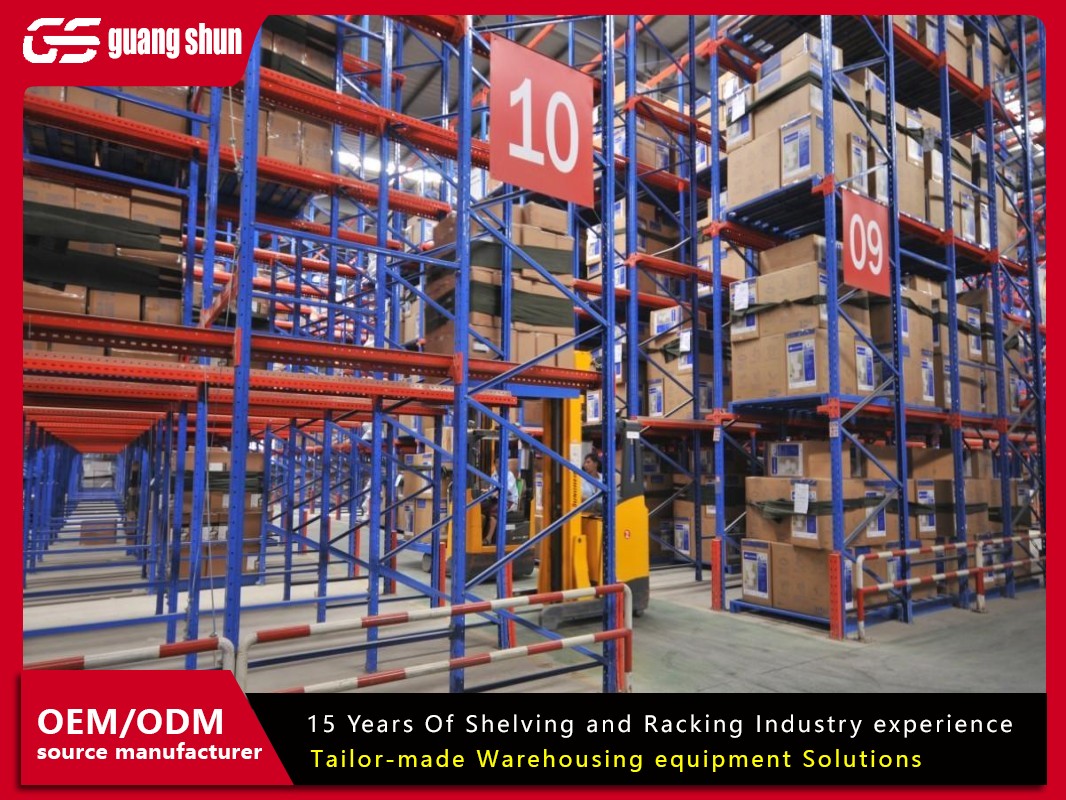

Selective pallet racking generally have a load capacity of 1000kg-3000kg per level, with the number of levels generally designed to be 3-5 and the height generally being 3-8 meters. It can be a single crossbeam racking, or it can be equipped with steel plates, wire mesh and cross beams together. As the size and shape of each enterprise’s warehouse vary, pallet racking usually has no standard size and is basically customized to fit the size of the customer’s warehouse.

The Selective Racking System is designed to maximize warehouse storage capacity by providing individual access to all pallets, maximizing vertical warehouse space. It enables seamless stock rotation and ensures efficient inventory management. Easily adjustable crossbars accommodate varying pallet heights. Furthermore, the Selective Racking System is compatible with all types of handling equipment, ensuring optimal workflow and safety.

1. Assembling the Columns

1) Connecting the Columns to the Cross Brace: Align the cross brace (horizontal connecting rod) with the pre-set holes in the columns and secure it with bolts. Do not tighten them yet to allow for subsequent fine-tuning.

2) Installing the Diagonal Braces: The diagonal braces are key components for enhancing stability and should be fixed diagonally inside the columns, ensuring proper alignment.

2. Erecting the Columns

1) Two-Person Collaboration: The columns are heavy, so it is recommended that two people work together to erect them to prevent them from tipping over.

2) Temporary Securing: After erecting, secure them with temporary supports or ropes, ensuring they are perpendicular to the ground. Use a level to calibrate.

3. Installing the Cross Beams

1) Attaching the Cross Beams: Insert both ends of the cross beam into the diamond-shaped or trapezoidal holes in the columns. A click indicates they are securely attached.

2) Symmetrical Installation: Install the bottom cross beam first, then proceed upwards. Ensure each cross beam is level to avoid uneven loads.

4. Lay out the steel plates/wire mesh (if applicable).

1) Select the decking type: Metal decking should rest directly on the beams. For wooden or steel decking, check the edges for flatness.

2) Evenly distribute the decking: After placing the decking, gently press the corners to ensure there is no warping and that the load does not exceed the specified value.

Crossbars: These are the primary supporting components of selective pallet racking. They are typically constructed of high-quality steel, offering high strength and load-bearing capacity, ensuring stable support for the weight of goods.

Uprights: These uprights provide vertical support and, in conjunction with the crossbars, form the rack's basic framework. They are typically made of square or round tubing with a rust-resistant surface treatment to ensure their longevity.

Footguards: These are installed at the bottom of the rack to protect the floor and prevent the rack from sliding. They are typically made of rubber or plastic and offer excellent anti-slip and shock-absorbing properties.

Connectors: These connect the crossbars and uprights, ensuring overall rack stability. Common connectors include nuts and bolts.

These racking components work together to create a powerful, stable, and reliable crossbar racking system that can meet the storage needs of various warehouses.

| L*D*H (mm) | 2450*1000*4875, 3660*1000*6700 (most common), customizable |

| Color | Blue, Orange, Customizable |

| Layer | 3Layer, 4Layer, 5Layer, Customizable |

| Load Capacity | 1000kg, 2000kg, 3000kg, Customizable |

| MOQ | 10 sets |

| Weight | about 125-155 kg |

| Volume | 0.30CBM |

| Estimated Delivery Time | 10-15 days |

1. Selective racking uses a single-row storage structure, with each pallet stored independently and accessible by standard forklifts.

Double-deep racking uses a double-row, parallel structure, requiring specialized forklifts for storage and retrieval.

Goods in the rear row must be moved or removed before accessing goods in the front row.

2. Double-deep racking increases warehouse utilization to approximately 42% through dual-row storage, but goods storage and retrieval must adhere to the LIFO principle, making it difficult to achieve FIFO.

While selective racking offers slightly lower warehouse utilization, it supports flexible storage and retrieval sequences, allowing for rapid inventory adjustments.

3. Double-deep racking is suitable for large storage volumes with low retrieval frequency, but may require access restrictions for goods in the rear row.

Selective racking is suitable for high-frequency storage and retrieval scenarios (such as e-commerce warehouses), enabling rapid inbound and outbound delivery.

Selective racking, equipped with the above systems, is the most flexible pallet racking system, offering 100% selectivity.

Wechat

Wechat

Whatsapp

Whatsapp