1. High-strength and tough H-shaped steel is used, offering excellent compression and bending resistance, a high load-bearing capacity, and a long service life.

2. Fast installation: The racking manufacturer manufactures the modules at the factory and assembles them on-site, shortening the installation cycle.

3. Easy maintenance and assembly: The modular structure of the steel mezzanine facilitates subsequent maintenance and assembly and disassembly for warehouse relocation.

4. The steel structural mezzanine design is flexible and can be designed and laid out based on the specific needs of the warehouse and the cargo, enabling multi-layered and multifunctional combinations.

5. The steel structural mezzanine maintains excellent corrosion resistance in various environments.

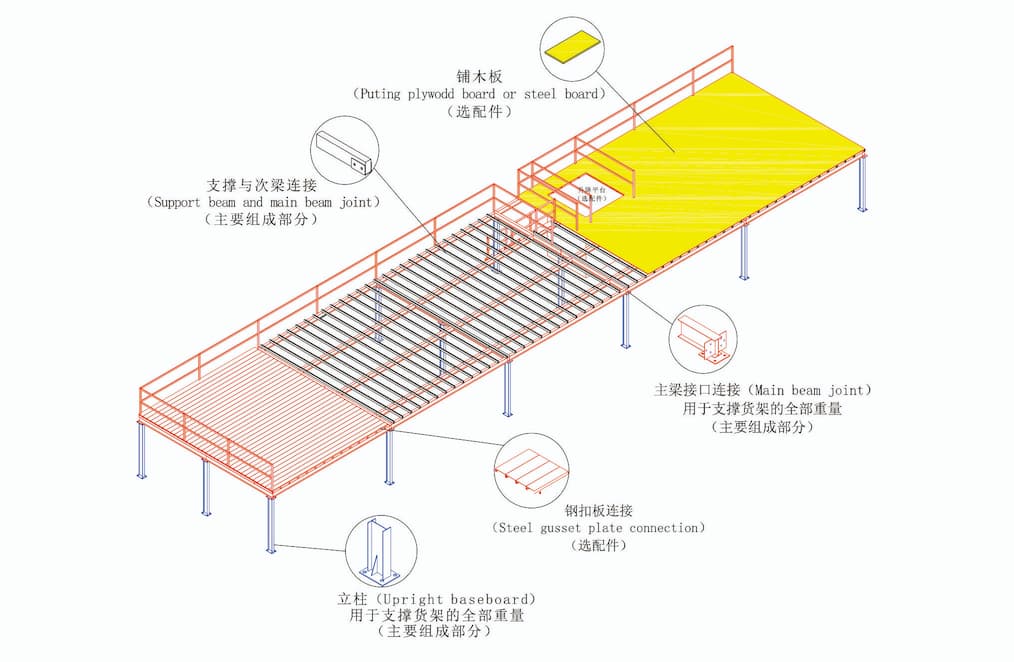

Before constructing a steel structural mezzanine, the dimensions, elevation, beam grid, and column grid of the steel structure platform must be determined. Consider the equipment load on the platform, the location of other large concentrated loads, and the weight of large-diameter suspension elements. Ensure the structure has sufficient compressive strength, flexural rigidity, and reliability.

The steel mezzanine floor panels must have anti-slip measures, such as anti-slip grooves or a coating. Guardrails are typically installed around the platform. The welds of the main components of the steel mezzanine must meet quality assurance standards.

Steel columns are the primary load-bearing components of a steel mezzanine floor, and their installation quality directly impacts the stability and safety of the entire platform. When installing steel columns, first determine their position and height according to the construction drawings and use a level and theodolite for alignment. Then, use a crane to lift the steel column to the designated location and secure it to the foundation with bolts or welding. During the securing process, ensure that the steel column's verticality and horizontality meet the design requirements.

After the steel columns are installed, the beams and slabs can be installed. First, determine the position and dimensions of the beams and slabs according to the construction drawings and use a crane to lift them to the designated location. Then, bolt or weld the beams and slabs to the steel columns. During the connection process, ensure the connection points are secure and stable. Also, pay attention to the flatness and verticality of the beams and slabs to ensure they meet the design requirements.

Welding is a critical step in the installation of steel structure mezzanines. Before welding, the welding materials and equipment must be inspected to ensure they meet construction requirements. During the welding process, the welding process requirements must be followed to ensure the quality and strength of the weld. After welding is completed, the weld must be inspected and accepted to ensure it meets design requirements. The stability and safety of the entire platform must also be checked to ensure compliance with relevant standards and regulations.

| Material | Cold-rolled Steel |

| Product size | Length: 2300 / 2500 / 2700 / 3000 / 3300 / 3600 / 3900 mm Width: 900 / 1000 / 1100 / 1200 mm Height: 2000-6500 mm |

| Thickness | column:1.5 mm, 2.0 mm |

| Load capacity | 500 kg-5000 kg per layer |

| Layers | 2-5 adjustable layers (can be custom made) |

| Color | RAL color; As per customer’s requirement |

| Surface | Electrostatic spray surface |

| Feature | Anti-rust, Corrosion-protection |

| Guarantee period | 5 years warranty |

| Remark | OEM & ODM accepted |

Four Main Methods for Mezzanine Foor Construction

When constructing a steel mezzanine, choosing the right method is crucial. The following are four mainstream steel floor construction methods, each with its own unique advantages and applicable scenarios.

1️⃣ Steel-Concrete Composite Floor:

This method combines a steel deck with a concrete slab, offering advantages such as high load capacity, low vibration, and excellent sound insulation. The specific steps include:

Using steel beams (I-beams) as structural support.

Laying corrugated steel sheets and securing them with studs.

Laying rebar.

Pouring a concrete screed.

2️⃣ Steel Lightweight Composite Floor:

This combines a steel structure with an aerated concrete slab, resulting in a lightweight, non-deformable structure and a short construction period. There are two installation methods: resting on the steel beam with hook bolts, or inserting it into the steel beam. A wire mesh is then laid over the floor, and cement mortar is used for leveling, with a thickness of 2-3 mm. The floor slab's length should not exceed 1.5 meters, and its load capacity should be 300 kg per square meter. It can be installed at the same height as the steel beams, maximizing space utilization.

3️⃣ Steel Structure and Steel Plate Combination Floor:

Suitable for industrial plants, workshops, and equipment rooms, this floor slab is constructed by combining a steel structure with patterned steel plates. Construction is quick, but insulation and sound insulation are limited.

4️⃣ Steel Structure Cement Board Combination Floor:

This method involves applying a cement base directly to the main structure. This method offers low cost, light weight, and a quick construction period, but offers less than ideal sound insulation and is suitable for smaller areas.

Each method has its own application scenarios and characteristics, and the choice should be carefully considered based on specific project requirements and conditions.

This space may not receive as generous sunlight and ventilation as other parts of the open space. Therefore, you might require installing a window in this space or creating vents to ensure the proper flow of air through the space to prevent health code violations.

The cost is affected by many factors, such as the height of the structural mezzanines, the material of the floor, the weight of each square meter, the size of the structural mezzanines, etc. Take a 300 square meter structural mezzanines with a load capacity of 500 kg per square meter and a floor height of 3 meters as an example, the price is about 70-110 USD per square meter. Want to know more detailed price? Call our sales staff at [email protected], our engineers will design a detailed plan and give you an estimate, contact us now to get a reference of the structural steel mezzanine structure we have done.

Wechat

Wechat

Whatsapp

Whatsapp