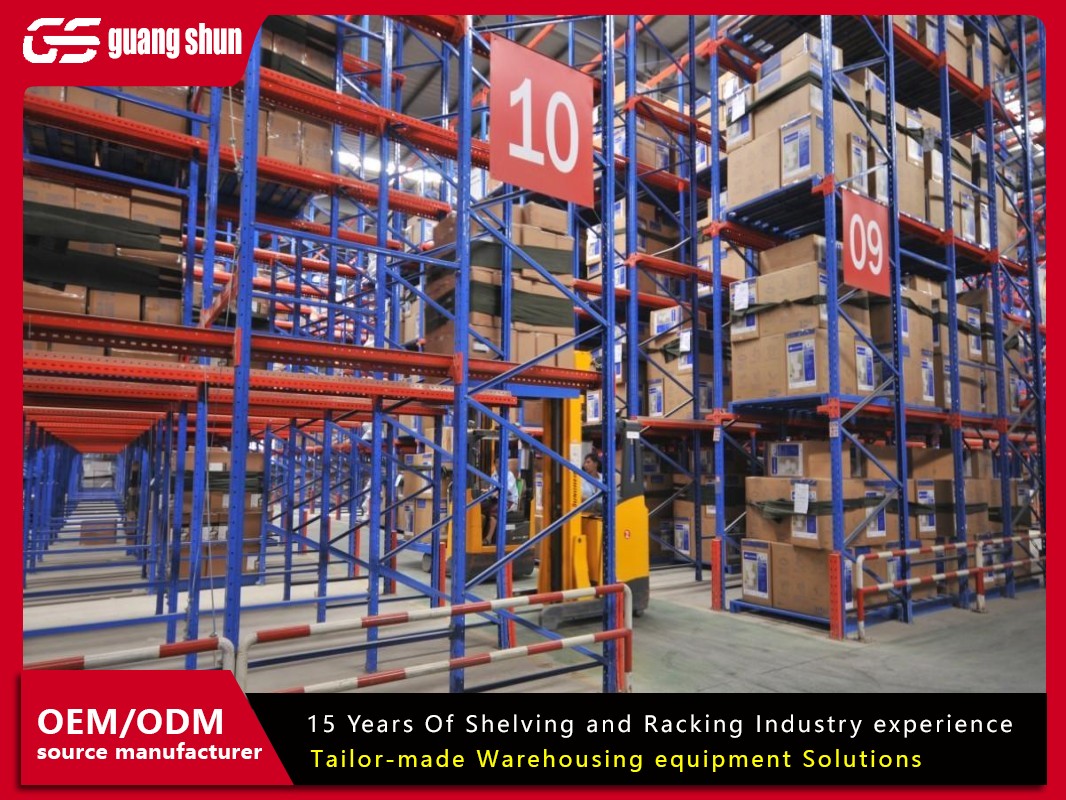

Shuttle Racking Systems (Semi-Automated)

Shuttle Racking Systems (Semi-Automated) Introduction

Optimize your high-volume, low-SKU inventory with Guangshun’s Radio Shuttle System. By utilizing remote-controlled shuttle carts to handle pallet movement within the lanes, you eliminate forklift travel time inside the racks, increasing safety and throughput by up to 60% compared to traditional drive-in systems.

GET QUOTE