Heavy duty shelves for storage is a very common type of pallet racking, with a load range of 800-5000 kg per layer.

Heavy duty shelves for storage utilizes forklifts for access, allowing for easy storage and retrieval of goods at desired locations, making it very convenient.

However, due to the need for forklifts, the rack aisles require significant space, resulting in low space utilization.

A single rack unit is typically less than 3.5 meters long and 0.8-1.4 meters wide, determined by the pallets.

Medium and low-height heavy-duty racking is generally under 12 meters tall, while super-high racking is typically under 25 meters (super-high racking is commonly found in automated warehouses).

The number of racking layers is designed based on the height of the goods and other factors.

Heavy duty shelves for storage has different design specifications than light- and medium-duty racking.

Light- and medium-duty racking typically accommodates small items, so conventional light- and medium-duty racking can meet these requirements.

Design considerations typically focus solely on the site. Heavy-duty racking, on the other hand, accommodates palletized goods.

Typically, a set of heavy-duty racks accommodates two pallets.

Therefore, the length and width of the racks are determined by the pallet specifications and the forklift entry direction.

The height and number of rack layers are determined by the height of the pallets, the site height, and the maximum lift height of the forklift.

Based on the weight of the goods, the specific materials used for each component are determined.

This determines the specifications for a single set of racks.

The overall design is then determined based on the site layout and forklift availability, determining the aisle dimensions.

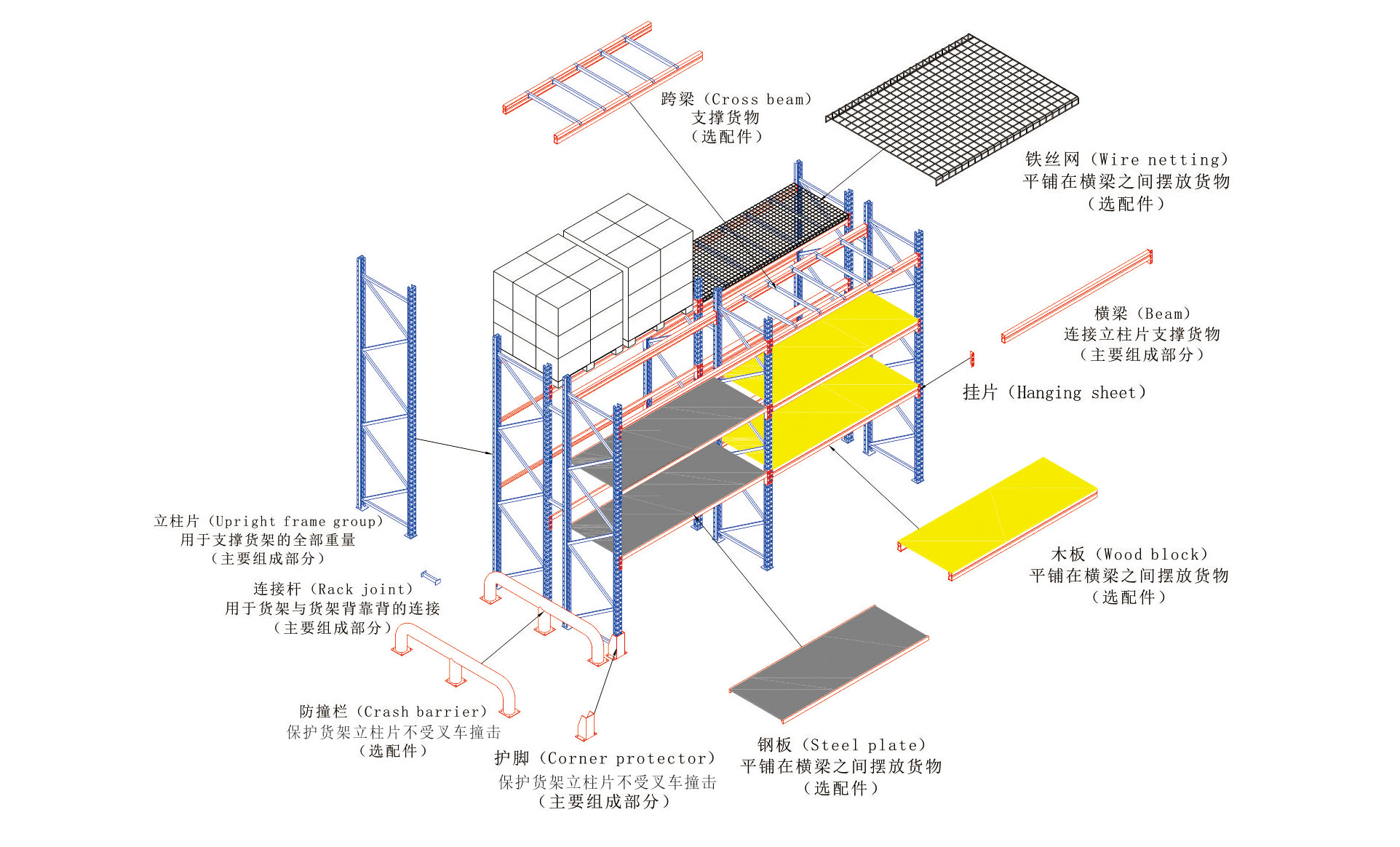

heavy-duty shelves Uprights: Consists of uprights, spacers, and horizontal and diagonal tie rods. The horizontal and diagonal tie rods are connected to the uprights via screws. Horizontal tie rods are installed at the upper and lower ends of the uprights, and diagonal tie rods are installed in the middle, spaced every 600mm between the uprights. The upright holes are diamond-shaped, spaced 75mm apart, so the crossbar can be adjusted in multiples of 75mm.

heavy-duty shelves Crossbars: Heavy-duty racking typically uses a truncated beam for its high load-bearing capacity. Hanging plates are welded on both sides of the beam, typically 3-foot plates (i.e., they insert into the three upright holes). For overweight cargo, 4-foot plates are used.

heavy-duty shelves Connecting rods: Racks are typically designed back-to-back, with connecting rods connecting two rows of racks. These connecting rods are typically 38*25 or 40*30 square tubes. The number of connecting rods varies depending on the rack height to enhance overall stability.

Safety accessories: The uprights at the ends of the racks are often vulnerable to forklift impacts. Guardian legs are designed to surround the uprights, providing forklift protection and enhancing rack safety.

Guardrail: At the end of the rack, a long circular tube is installed along the entire column to withstand forklift impacts. It provides a wide range of protection and acts like a reinforced protective leg.

heavy duty shelves for storage, also known as beam racking or shelf racking, is a type of pallet racking and one of the most widely used types of warehouse racking systems in China. It can be used in conjunction with a variety of storage unit container equipment, such as partitions, steel shelves, wire mesh shelves, storage cage rails, and oil drum racks, to meet different cargo storage needs.

Wechat

Wechat

Whatsapp

Whatsapp