In today's fast-paced industrial and logistics sectors, maximizing storage space while maintaining accessibility and safety is a constant challenge. If you're managing a warehouse, distribution center, or any facility with substantial inventory, you've likely encountered the term "long span pallet racking." But what exactly is it, and why is it gaining popularity? This article dives deep into long span pallet racking, exploring its benefits, applications, and practical considerations to help you make informed decisions for your storage needs. Unlike generic guides, we'll focus on real-world insights without the fluff, so you can grasp how this system can transform your operations.

Long span pallet racking is a type of storage system designed to handle heavier loads over wider spans compared to traditional racking. Essentially, it features beams that span longer distances between upright frames, allowing for larger pallet placements and reduced need for vertical supports. This design is ideal for storing bulky or irregularly shaped items, as it provides clear, open spaces that enhance visibility and accessibility. Typically constructed from high-strength steel, long span pallet racking systems are engineered to support significant weight while optimizing floor space. They are a staple in industries where efficiency and flexibility are paramount, such as manufacturing, retail, and logistics. By understanding the basics of long span pallet racking, you can appreciate why it's a go-to solution for many businesses looking to streamline their storage processes.

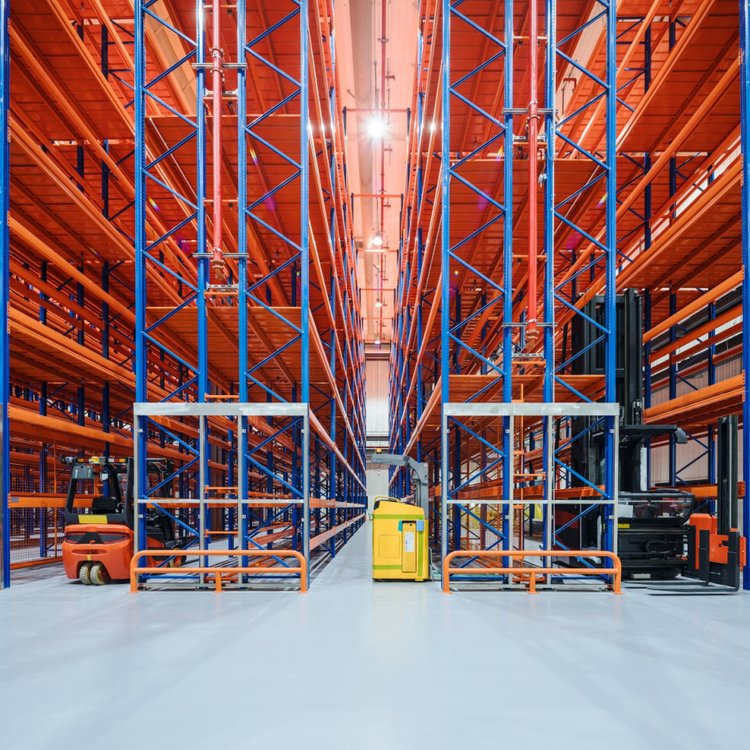

Why should you consider long span pallet racking for your facility? The advantages are numerous, starting with its ability to maximize storage density. With longer spans, you can store more pallets in a given area, reducing clutter and improving workflow. This is particularly useful in warehouses with high ceilings, as it allows for better vertical space utilization. Additionally, long span pallet racking offers enhanced flexibility; beams can be adjusted easily to accommodate different pallet sizes or inventory changes. This adaptability means you won't need a complete overhaul when your storage requirements evolve.

Safety is another critical benefit. The robust construction of long span pallet racking minimizes the risk of collapses or accidents, especially when paired with proper installation and maintenance. Compared to shorter-span systems, it often requires fewer connections and components, simplifying inspections and reducing potential failure points. Cost-effectiveness also comes into play—though the initial investment might be higher, the long-term savings in space optimization and reduced handling time can lead to a quicker return on investment. In essence, long span pallet racking isn't just about storage; it's about building a resilient, scalable infrastructure that supports business growth.

Long span pallet racking isn't limited to one sector; its versatility makes it suitable for a wide range of applications. In manufacturing plants, it's used to store raw materials and finished goods, enabling just-in-time production processes. Distribution centers rely on long span pallet racking to manage high-volume shipments, where quick access and efficient sorting are crucial. Retail warehouses benefit from its ability to handle diverse product sizes, from appliances to seasonal items, ensuring smooth inventory turnover.

Cold storage facilities also find long span pallet racking invaluable, as its design allows for better air circulation and easier cleaning, complying with hygiene standards. Even in automotive or aerospace industries, where parts can be large and heavy, this system provides the strength and span needed to organize components safely. By integrating long span pallet racking, businesses across these fields report improved operational efficiency and reduced downtime. It's a testament to how this storage solution can be tailored to meet specific industry demands, making it a smart choice for any operation dealing with substantial inventory.

Selecting the appropriate long span pallet racking for your needs involves several factors. First, assess your inventory characteristics—consider the weight, size, and type of items you'll store. Long span pallet racking is ideal for heavier loads, but you'll need to verify the weight capacity to avoid overloading. Next, evaluate your space constraints. Measure the available floor area and ceiling height to determine the optimal rack configuration. A common mistake is overlooking future growth; choose a system that allows for easy expansion or reconfiguration.

Durability and material quality are also key. Look for systems made from galvanized or powder-coated steel to resist corrosion, especially in humid environments. Installation requirements shouldn't be ignored—while some long span pallet racking setups are DIY-friendly, professional installation is recommended for complex layouts to ensure safety and compliance with local regulations. Lastly, consider integration with other warehouse equipment, like forklifts or automated retrieval systems. A well-chosen long span pallet racking system should complement your overall workflow, not hinder it. By taking these steps, you can avoid costly errors and invest in a solution that delivers lasting value.

When it comes to cost, long span pallet racking can vary widely based on factors like material, size, and customization. On average, prices range from a few hundred to several thousand dollars per bay, depending on the load capacity and additional features. It's essential to view this as a long-term investment rather than an upfront expense. For instance, higher-quality long span pallet racking might have a steeper initial cost but lower maintenance expenses over time. Budget for ancillary costs too, such as installation, permits, and potential reinforcements to your building's structure.

To get the best value, obtain quotes from multiple suppliers and compare the total cost of ownership, including warranty and support services. Leasing options might be available if capital is tight, but purchasing often provides better ROI. Remember, skimping on quality can lead to safety issues and frequent replacements, which ultimately cost more. By carefully analyzing your budget and needs, you can find a long span pallet racking system that balances affordability with performance, ensuring it pays off in enhanced productivity and space savings.

Delving into the technical aspects, long span pallet racking relies on precise engineering to handle stress and weight distribution. The beams are typically roll-formed or structural steel, with spans that can exceed 10 feet in some configurations. Key components include upright frames, beam connectors, and safety locks, all designed to withstand dynamic loads and seismic activities if applicable. Proper installation is crucial; it starts with a site assessment to check floor levelness and load-bearing capacity. Anchoring the racking securely to the ground prevents shifting, especially in high-traffic areas.

Regular inspections are part of maintaining long span pallet racking integrity. Look for signs of wear, such as bent beams or loose connections, and address them promptly. Training staff on safe loading practices—like evenly distributing weight and avoiding overloading—can prevent accidents. For those considering upgrades, technologies like RFID tagging or integration with warehouse management systems can enhance the functionality of long span pallet racking. By adhering to these technical guidelines, you ensure the system operates efficiently and safely, extending its lifespan and protecting your investment.

Sourcing long span pallet racking requires careful vendor selection to ensure quality and support. Start by researching suppliers with proven experience in industrial storage solutions. Look for companies that offer customization, as one-size-fits-all approaches rarely suffice for complex needs. Check reviews and ask for case studies or references to gauge reliability. It's also wise to inquire about after-sales services, such as maintenance contracts or emergency repairs, which can be invaluable for minimizing downtime.

When evaluating proposals, compare not just prices but also lead times, warranty terms, and compliance with industry standards like OSHA or RMI. Local suppliers might offer faster service, but national providers could have broader product ranges. Don't hesitate to request on-site consultations—many reputable suppliers will assess your space and recommend optimized long span pallet racking setups. By building a partnership with a trusted provider, you can ensure a smooth implementation process and ongoing support, making your transition to long span pallet racking as seamless as possible.

Q1: What is the maximum weight capacity for long span pallet racking?

A1: The weight capacity for long span pallet racking varies based on the beam design and material, but it can typically support loads ranging from 1,000 to 10,000 pounds per beam. Always consult with a supplier or engineer to determine the exact capacity for your specific setup, as factors like span length and upright frame strength play a crucial role.

Q2: How does long span pallet racking compare to selective pallet racking?

A2: Long span pallet racking is designed for wider spans and heavier loads, making it better for bulky items, while selective pallet racking offers more vertical levels and is ideal for high-density storage of uniform pallets. Long span versions provide greater accessibility and flexibility but may require more floor space per bay compared to selective systems.

Q3: Can long span pallet racking be used in outdoor environments?

A3: Yes, but it requires additional protections like weather-resistant coatings or galvanized steel to prevent rust and corrosion. Regular maintenance is essential in outdoor settings to ensure longevity and safety, as exposure to elements can accelerate wear.

Q4: What are the common maintenance tips for long span pallet racking?

A4: Regularly inspect for damage, such as dents or cracks, clean debris from beams and connectors, and ensure all bolts are tight. Avoid overloading and train staff on proper usage. Scheduling professional inspections annually can help identify issues early and maintain optimal performance.

Q5: Is long span pallet racking customizable for unique warehouse layouts?

A5: Absolutely—many suppliers offer customization options for beam lengths, heights, and configurations to fit irregular spaces or specific operational needs. Discuss your layout details with a provider to design a system that maximizes efficiency without compromising safety.

In conclusion, long span pallet racking is a powerful tool for enhancing storage efficiency, offering a blend of strength, flexibility, and cost savings. By considering the insights shared here, you can implement a system that meets your unique demands and drives operational success. If you have more questions, feel free to reach out to industry experts for personalized advice.

Wechat

Wechat

Whatsapp

Whatsapp