When it comes to warehouse storage systems, understanding pallet rack upright capacity is crucial for ensuring safety, optimizing space, and preventing costly accidents. Pallet rack upright capacity refers to the maximum load that the vertical frames of a pallet rack can safely support. This capacity is a key factor in designing and maintaining efficient storage solutions, as it directly impacts the structural integrity of the entire racking system. In this article, we'll delve into the critical aspects of pallet rack upright capacity, covering its definition, influencing factors, calculation methods, safety considerations, and maintenance practices. By the end, you'll have a comprehensive understanding of how to manage and maximize pallet rack upright capacity in your operations.

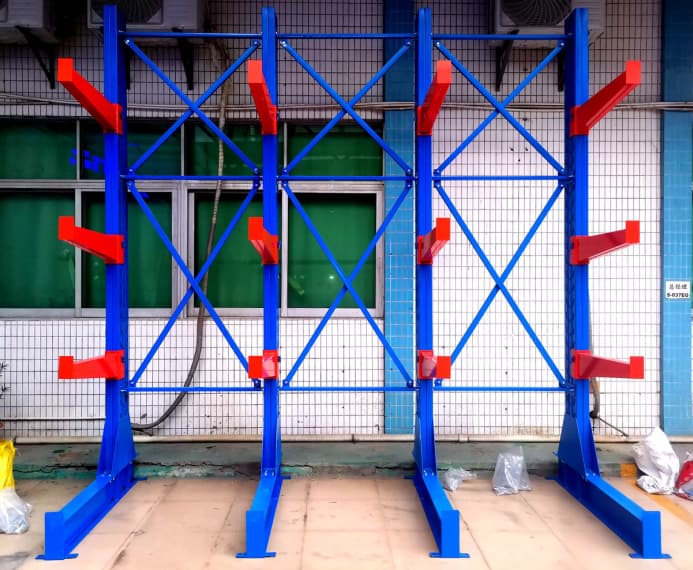

Pallet rack upright capacity is the maximum weight that the vertical components of a pallet rack system can bear without compromising safety or structural stability. These uprights, often made of steel, form the backbone of the racking system, supporting the beams and the loads placed on them. The pallet rack upright capacity is determined by factors such as the material strength, design geometry, and manufacturing standards. It's essential to distinguish this from beam capacity, as uprights handle the cumulative weight from multiple levels, making their capacity a critical consideration in warehouse planning. Ignoring pallet rack upright capacity can lead to overloading, which may cause buckling, collapse, or damage to stored goods, posing significant risks to personnel and operations. Therefore, always refer to manufacturer specifications and industry standards when assessing pallet rack upright capacity for your specific setup.

Several elements influence pallet rack upright capacity, and understanding these can help you make informed decisions for your storage needs. First, the material composition plays a vital role; high-strength steel uprights typically offer higher capacity compared to lighter alloys. Second, the design and geometry, including the upright's height, width, and bracing patterns, affect how loads are distributed and resisted. For instance, taller uprights may have reduced capacity due to increased susceptibility to bending moments. Third, environmental conditions like temperature fluctuations, humidity, and exposure to chemicals can degrade materials over time, lowering the effective pallet rack upright capacity Additionally, the type and distribution of loads—whether uniform or concentrated—impact capacity, as uneven weight distribution can stress specific points. Finally, installation quality and adherence to guidelines are crucial; improper assembly can significantly reduce the intended pallet rack upright capacity. By evaluating these factors, you can select the right uprights and avoid potential hazards.

Calculating pallet rack upright capacity involves a combination of engineering principles and practical assessments. Typically, manufacturers provide capacity charts based on standardized tests, which consider the upright's dimensions, material properties, and load configurations. To determine the required pallet rack upright capacity for your warehouse, start by summing the total weight of palletized goods per upright section, including the weight of beams and any dynamic loads from equipment like forklifts. Then, apply safety factors as per industry standards, such as those from the Rack Manufacturers Institute (RMI) or OSHA, which often recommend a safety margin of 1.5 to 2 times the expected load to account for uncertainties. For custom setups, consulting a structural engineer is advisable to perform detailed calculations that consider factors like seismic activity or wind loads in open warehouses. Regularly reviewing these calculations ensures that your pallet rack upright capacity remains adequate as storage needs evolve, preventing overloading and promoting longevity.

Safety is paramount when dealing with pallet rack upright capacity, as failures can lead to severe injuries and financial losses. Always ensure that the pallet rack upright capacity is not exceeded by conducting regular load audits and using weight indicators on racks. Implement clear labeling of capacity limits on uprights to guide warehouse staff, and provide training on proper loading techniques to avoid uneven distribution. Additionally, consider the impact of accidental impacts from machinery; installing protective guards can help maintain the upright's integrity and preserve its capacity. Compliance with regulations like OSHA guidelines and ANSI MH16.1 standards is essential to mitigate risks. In high-risk environments, such as those with frequent pallet movement, periodic inspections by certified professionals can identify signs of wear or damage that might compromise pallet rack upright capacity. By prioritizing safety, you not only protect assets but also enhance operational efficiency.

Proper maintenance is key to sustaining pallet rack upright capacity over time. Start with routine visual inspections to check for signs of corrosion, dents, or misalignment in the uprights, as these can reduce capacity. Clean the racks regularly to prevent debris accumulation, which might add unintended load or cause corrosion. If modifications are needed, such as adding new beams or adjusting heights, recalculate the pallet rack upright capacity to ensure it remains within safe limits. For optimization, consider retrofitting with higher-capacity uprights or using reinforcement kits in high-stress areas. Implementing a warehouse management system that tracks load data can help monitor usage patterns and prevent overloading. Remember, proactive maintenance not only extends the lifespan of your racks but also ensures that the pallet rack upright capacity is fully utilized without compromising safety, leading to cost savings and improved productivity.

Q1: What is the difference between pallet rack upright capacity and beam capacity?

A1: Pallet rack upright capacity refers to the maximum load the vertical frames can support, while beam capacity relates to the horizontal beams that hold the pallets. Uprights bear the cumulative weight from all levels, making their capacity critical for overall stability, whereas beams handle individual shelf loads. Both must be balanced to ensure safety.

Q2: How often should I inspect my pallet rack upright capacity?

A2: It's recommended to conduct visual inspections monthly and professional assessments annually, or after any significant impact or change in load patterns. Regular checks help identify issues early, ensuring that the pallet rack upright capacity remains adequate and reducing the risk of failures.

Q3: Can environmental factors affect pallet rack upright capacity?

A3: Yes, factors like humidity, temperature extremes, and exposure to chemicals can cause corrosion or material degradation, potentially reducing the pallet rack upright capacity over time. Using protective coatings and storing racks in controlled environments can mitigate these effects.

Q4: What should I do if I exceed the pallet rack upright capacity?

A4: If you accidentally exceed the capacity, immediately redistribute the load to reduce stress on the uprights and inspect for any damage. Consult a professional to assess the rack's integrity and consider upgrading to higher-capacity uprights if needed to prevent future risks.

Q5: Are there industry standards for pallet rack upright capacity?

A5: Yes, organizations like the Rack Manufacturers Institute (RMI) and OSHA provide guidelines and standards for pallet rack upright capacity. Adhering to these ensures compliance and safety, and manufacturers often test their products according to these benchmarks to provide reliable capacity ratings.

By focusing on these aspects of pallet rack upright capacity, you can create a safer, more efficient warehouse environment. Always prioritize accurate assessments and ongoing maintenance to maximize the benefits of your storage systems.

Wechat

Wechat

Whatsapp

Whatsapp