In today's fast-paced industrial and commercial environments, efficient storage solutions are crucial for maximizing productivity and minimizing costs. Among the various options available, pallet shelving systems stand out as a versatile and reliable choice for businesses of all sizes. These systems are specifically designed to handle heavy loads, optimize space, and streamline operations in warehouses, distribution centers, and retail settings. By incorporating robust materials and adaptable designs, pallet shelving systems provide a solid foundation for organizing goods safely and accessibly. This article delves into the essential aspects of pallet shelving systems, highlighting their benefits, types, installation processes, applications, and maintenance tips. Whether you're looking to upgrade your current setup or implement a new storage strategy, understanding these systems can help you make informed decisions that enhance overall efficiency.

Pallet shelving systems are specialized storage structures engineered to support and organize palletized goods. Typically constructed from high-strength steel, these systems feature upright frames, beams, and shelving decks that can withstand substantial weight. The design allows for easy loading and unloading using forklifts or pallet jacks, making them ideal for handling bulk items. Unlike standard shelving, pallet shelving systems are built to accommodate the dimensions and weight distribution of standard pallets, which are commonly used in logistics and supply chain management. This ensures that goods are stored securely, reducing the risk of damage and improving inventory management. By integrating these systems, businesses can create a structured storage environment that supports high-density stacking and efficient retrieval processes. The adaptability of pallet shelving systems means they can be customized to fit various space constraints and operational needs, providing a scalable solution as business demands evolve.

One of the primary advantages of pallet shelving systems is their ability to maximize vertical space, allowing businesses to store more goods in a smaller footprint. This is particularly beneficial in urban areas where real estate costs are high. Additionally, these systems enhance safety by reducing clutter and preventing accidents related to improper storage. The durability of materials used in pallet shelving systems ensures long-term reliability, even in demanding environments. Another significant benefit is improved accessibility; with clear aisles and organized layouts, workers can quickly locate and retrieve items, boosting productivity. Cost-effectiveness is also a key factor, as pallet shelving systems often require minimal maintenance and can be reconfigured to meet changing needs without significant investment. By leveraging these benefits, companies can achieve better inventory control, faster order fulfillment, and overall operational excellence. The versatility of pallet shelving systems makes them suitable for a wide range of industries, from manufacturing to e-commerce, where efficient storage is paramount.

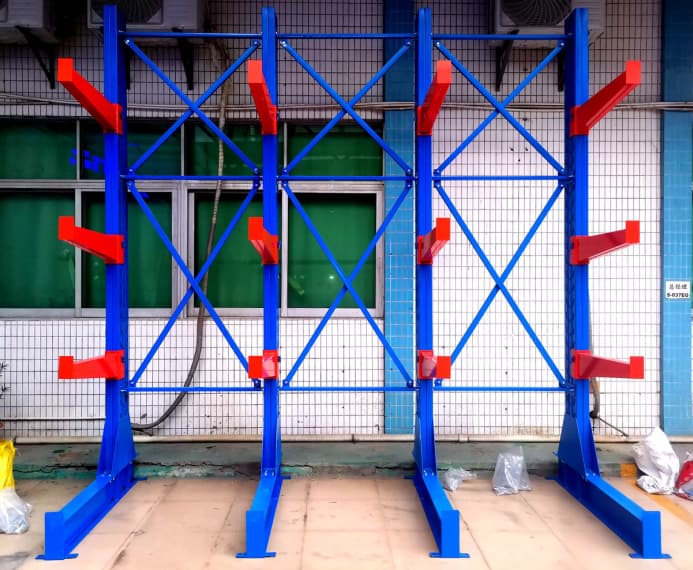

Pallet shelving systems come in various configurations to suit different storage requirements. The most common types include selective pallet racking, which allows direct access to each pallet, making it ideal for high-turnover inventory. Drive-in and drive-through systems are designed for high-density storage by eliminating aisles, enabling forklifts to enter the racking structure to store and retrieve pallets. Another popular design is push-back racking, which uses a last-in, first-out (LIFO) system to maximize space utilization. Cantilever shelving systems are specialized for storing long, bulky items like pipes or lumber, while still incorporating principles of pallet shelving systems for stability. Each type offers unique features, such as adjustable beam heights and modular components, allowing for customization based on load capacity and space availability. Understanding these options helps businesses select the right pallet shelving systems for their specific needs, ensuring optimal performance and efficiency. By evaluating factors like inventory flow, item size, and frequency of access, companies can implement a system that aligns with their operational goals.

Proper installation is critical to the safety and functionality of pallet shelving systems. It begins with a thorough assessment of the storage area, including floor conditions, ceiling height, and load requirements. Professional installation is recommended to ensure that components are assembled correctly and anchored securely, preventing collapses or accidents. Regular maintenance is equally important; this includes inspecting for damage, such as bent beams or loose connections, and cleaning to prevent debris buildup. Lubricating moving parts in adjustable systems can extend their lifespan. Additionally, training staff on proper loading techniques—such as evenly distributing weight and not exceeding capacity limits—helps maintain the integrity of pallet shelving systems. Implementing a routine inspection schedule and keeping detailed records of maintenance activities can prevent costly repairs and downtime. By adhering to these best practices, businesses can ensure their pallet shelving systems remain reliable and safe over time, supporting continuous operations and reducing the risk of inventory loss.

Pallet shelving systems are widely used across numerous industries due to their versatility and strength. In warehousing and distribution, they facilitate efficient storage of goods, enabling quick order processing and shipping. Manufacturing plants utilize these systems to organize raw materials and finished products, streamlining production lines. Retail businesses benefit from pallet shelving systems in backrooms to manage overstock and seasonal items. The food and beverage industry relies on them for storing bulk ingredients and packaged goods, often in temperature-controlled environments. Even sectors like agriculture and automotive use pallet shelving systems for tools, parts, and equipment. The adaptability of these systems allows for integration with other storage solutions, such as mezzanines or conveyor systems, creating a cohesive logistics network. By understanding the diverse applications, businesses can tailor their pallet shelving systems to meet industry-specific challenges, such as hygiene standards in pharmaceuticals or heavy-duty requirements in construction. This widespread reliance underscores the importance of pallet shelving systems in modern supply chains.

Investing in pallet shelving systems involves evaluating upfront costs against long-term returns. Initial expenses include the purchase of components, installation fees, and any necessary site preparations. However, the durability and scalability of pallet shelving systems often lead to significant cost savings over time. By optimizing space, businesses can reduce the need for additional storage facilities, lowering rental or construction costs. Improved efficiency translates to faster operations and reduced labor expenses, while enhanced safety minimizes accident-related costs. Calculating the return on investment (ROI) involves considering factors like increased storage capacity, reduced product damage, and higher throughput. Many companies find that pallet shelving systems pay for themselves within a few years through these efficiencies. Additionally, modular designs allow for incremental expansions, spreading out costs as business grows. By conducting a thorough cost-benefit analysis, organizations can justify the investment in pallet shelving systems and plan for future upgrades, ensuring they remain competitive in their respective markets.

Q1: What is the average weight capacity of pallet shelving systems?

A1: The weight capacity of pallet shelving systems varies based on design and materials, but standard systems can typically support between 1,000 to 5,000 pounds per level. It's essential to consult manufacturer specifications and consider factors like beam strength and deck type to ensure safe loading.

Q2: Can pallet shelving systems be customized for irregularly shaped items?

A2: Yes, pallet shelving systems are highly customizable. Options like adjustable beams, varied deck sizes, and accessories such as dividers or wire mesh can accommodate irregular shapes. Cantilever designs are particularly suited for long or bulky items.

Q3: How do I determine the right height for my pallet shelving systems?

A3: The ideal height depends on your ceiling clearance, forklift reach, and safety regulations. Generally, pallet shelving systems can range from 10 to 30 feet tall. A professional assessment can help optimize height for space utilization and accessibility.

Q4: Are pallet shelving systems easy to relocate if I move facilities?

A4: Many pallet shelving systems are designed with modular components, making disassembly and relocation feasible. However, it's advisable to plan the move carefully to avoid damage and ensure reassembly follows safety standards.

Q5: What maintenance is required for pallet shelving systems to ensure longevity?

A5: Regular maintenance includes visual inspections for damage, tightening loose bolts, cleaning debris, and ensuring loads are within capacity. Annual professional check-ups are recommended to address wear and tear, extending the life of your pallet shelving systems.

In conclusion, pallet shelving systems are a cornerstone of effective storage management, offering flexibility, durability, and efficiency. By exploring their various aspects, businesses can harness these benefits to drive growth and operational success.

Wechat

Wechat

Whatsapp

Whatsapp