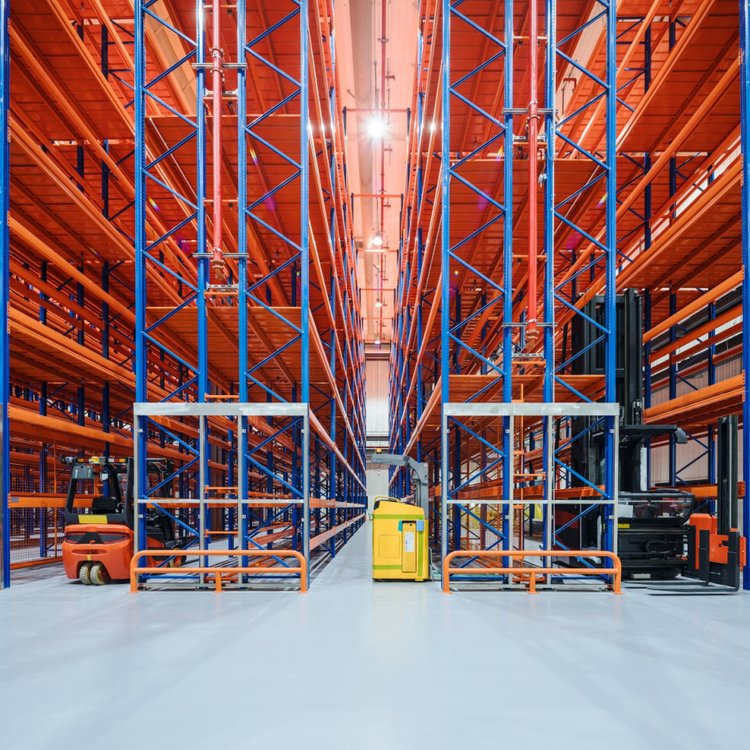

In the fast-paced world of logistics and inventory management, the backbone of any efficient operation is a well-designed storage system. This is where warehouse racking companies come into play. These specialized firms provide the critical infrastructure—the warehouse rack and warehouse pallet racking—that allows businesses to maximize space, improve organization, and streamline workflows. Whether you're building a new facility, expanding an existing one, or simply optimizing your current layout, choosing the right partner is paramount. A search for "warehouse racking companies near me" yields many options, but how do you discern the best from the rest? This comprehensive guide will walk you through everything you need to know about selecting, working with, and maintaining systems from top warehouse racking installation companies, ensuring your investment drives productivity and safety for years to come.