Warehouse operations demand smart storage solutions to handle growing inventory. A push rack system offers a dynamic approach to organizing goods. It uses gravity to move pallets, saving space and streamlining access. This article explores five practical methods a push rack system enhances storage efficiency. We will cover benefits, applications, and selection tips.

A push rack system is a high-density storage solution. It stores multiple pallets in a single lane. Pallets are loaded from one end and pushed forward as items are removed. This design maximizes floor space usage.

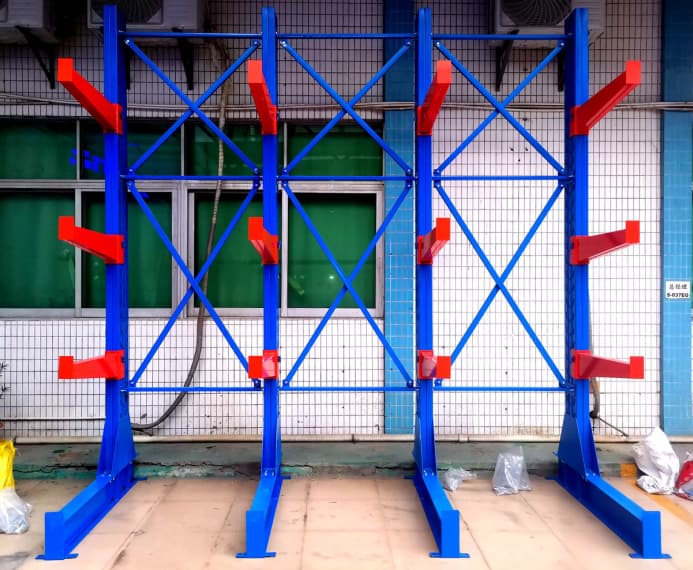

The system includes several key parts. These ensure smooth operation and safety.

Rails or Tracks: Guide pallets along the lane.

Push Back Carts: Move pallets using gravity or slight force.

Frame Structure: Supports the entire setup securely.

Safety Brakes: Prevent accidental movement of pallets.

Pallets are placed on inclined rails. When a new pallet is loaded, it pushes existing ones forward. Retrieval involves removing the front pallet. The others slide into position automatically. This process supports FIFO (First-In, First-Out) inventory management.

Implementing a push rack system brings multiple advantages. These benefits help warehouses operate more effectively.

This system reduces aisle space. More pallets fit into the same area. It can boost storage capacity by up to 75% compared to traditional racks. This is ideal for facilities with limited space.

The push rack system naturally enforces FIFO flow. Older inventory is accessed first. This reduces spoilage and waste. It is crucial for perishable goods like food or pharmaceuticals.

Workers spend less time moving pallets. Automated sliding minimizes manual handling. This speeds up loading and unloading processes. It also lowers labor costs over time.

Built-in brakes and secure rails prevent accidents. Pallets move smoothly without sudden shifts. This reduces risks of damage or injury in busy warehouses.

Systems can be expanded easily. Add more lanes or levels as inventory grows. A push rack system adapts to changing business needs without major overhauls.

Many sectors use push rack systems to optimize storage. Their design suits specific inventory requirements.

Perishable items need strict rotation. A push rack system ensures FIFO compliance. It helps manage bulk goods like canned foods or beverages efficiently.

Medicines often have expiration dates. This system maintains proper stock rotation. It also keeps sensitive items organized and accessible.

High-volume products require fast turnover. A push rack system streamlines order picking. It supports quick restocking and reduces handling errors.

Selecting a push rack system requires careful planning. Consider these factors to match your warehouse needs.

Assess inventory types and volumes. Determine pallet sizes and weights. This helps design a system that handles your specific goods.

Check the maximum weight per lane. Ensure the push rack system can support your heaviest pallets. Overloading can cause damage or safety issues.

Think about long-term growth. Choose a modular system that allows easy additions. This avoids costly replacements later.

Proper setup and care extend the life of your push rack system. Follow these guidelines for optimal performance.

Hire experienced installers. They ensure rails are level and secure. Correct installation prevents operational problems. Always follow manufacturer instructions.

Regular inspections keep the system running smoothly. Focus on key areas to avoid downtime.

Inspect rails for wear or damage monthly.

Lubricate moving parts every six months.

Test safety brakes quarterly.

Clean debris from lanes to prevent jams.

A push rack system is a valuable investment for modern warehouses. It boosts storage density, improves inventory management, and cuts labor costs. By selecting the right system and maintaining it well, businesses can achieve long-term efficiency. Consider implementing a push rack system to enhance your storage operations today.

Q1: What is the main advantage of a push rack system?

A1: The primary advantage is increased storage density. It allows more pallets in less space by reducing aisle needs. This makes it efficient for warehouses with limited area.

Q2: Can a push rack system handle heavy loads?

A2: Yes, most systems are designed for heavy loads. However, check the specific load capacity before purchase. Ensure it matches your inventory weight to prevent issues.

Q3: Is a push rack system suitable for cold storage?

A3: Absolutely. These systems work well in cold environments. They are often used for frozen goods or perishables. Choose materials resistant to low temperatures.

Q4: How does a push rack system compare to drive-in racks?

A4: Push rack systems offer better inventory rotation. They support FIFO, while drive-in racks may use LIFO. Push racks also reduce forklift entry needs, enhancing safety.

Q5: What maintenance does a push rack system require?

A5: Regular maintenance includes inspecting rails, lubricating parts, and testing brakes. Clean lanes periodically to ensure smooth operation. Follow manufacturer guidelines for details.

Wechat

Wechat

Whatsapp

Whatsapp