Running a warehouse is a constant battle against space. One day, you have plenty of room to maneuver forklifts, and the next, you are stacking pallets in the aisles because there is nowhere else to put them. This is where the right infrastructure makes or breaks your operation.

Investing in high-quality racking shelves for warehouse storage is the most effective way to regain control of your floor plan. It isn't just about buying metal beams; it is about engineering a workflow that saves time and money.

Whether you are fitting out a brand-new facility or reorganizing a cluttered distribution center, selecting the right system is a massive decision. This article breaks down the essential factors you need to consider to get the most out of your vertical space.

Before you look at a single catalog, look at your products. The biggest mistake facility managers make is buying a generic system that doesn't fit their specific goods.

If you handle perishable food items, your needs are completely different from a company storing steel pipes. You need to determine if your operation runs on a First-In, First-Out (FIFO) or Last-In, First-Out (LIFO) basis.

For FIFO operations, you need racking shelves for warehouse layouts that allow for easy rotation. Pallet flow racks or standard selective racks are usually best here. If you buy a deep-lane system for goods that expire, you are going to lose money on spoilage.

Consider the weight and dimensions of your typical load. A standard pallet might fit on most racks, but if you have oversized SKUs, you need customizable racking shelves for warehouse configurations that can handle the overhang and heavy point loads without buckling.

When most people think of industrial storage, they picture selective racking. This is the most common type of racking shelves for warehouse use, and for good reason.

Selective racking is versatile. It gives you direct access to every single pallet. You don't have to move one pallet to get to another. This is excellent for businesses with a high number of different SKUs (Stock Keeping Units) but lower volumes of each.

The downside is density. Because you need an aisle for every row of racks, you are using a lot of floor space for forklift travel. However, if speed and immediate access are your top priorities, selective racking shelves for warehouse systems are usually the best starting point.

They are also the most affordable option upfront. Installation is straightforward, and parts are easy to replace if a forklift driver accidentally bumps a vertical upright.

If you have a massive amount of the same product—say, 500 pallets of the exact same tile or beverage—selective racking is a waste of space. You need density.

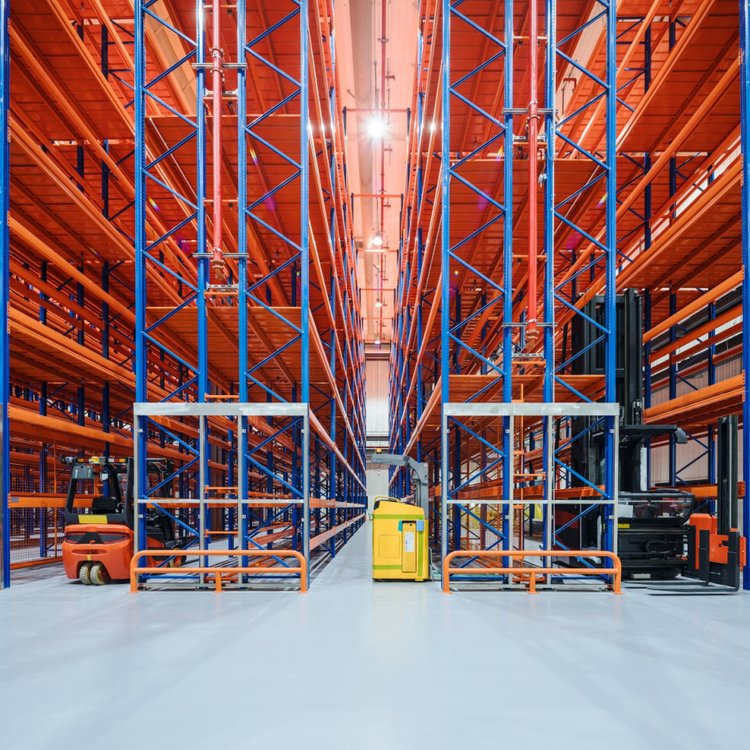

Drive-in and drive-through racking shelves for warehouse systems allow forklifts to enter the rack structure itself to place and retrieve pallets. This eliminates the need for so many aisles. You can store pallets six, seven, or even more positions deep.

This is a LIFO (Last-In, First-Out) system. The last pallet you put in is the first one you have to take out. It is perfect for bulk storage where stock rotation isn't the primary concern.

However, these systems require skilled forklift operators. Because the driver enters the racking shelves for warehouse structure, the risk of collision is higher. You need robust column guards and heavy-duty steel construction to handle the inevitable bumps.

Not everything fits neatly on a 40x48 pallet. If you store lumber, PVC piping, steel bars, or furniture, standard pallet racks are a nightmare. You end up wasting space or creating dangerous stacking situations.

This is where cantilever racking shelves for warehouse applications shine. These racks use a central column with arms extending out, leaving the front completely open. There are no vertical posts to block long items.

You can load a 20-foot pipe across multiple arms easily. When shopping for racking shelves for warehouse setups for awkward items, verify the weight capacity of the individual arms. You also need to ensure the base is anchored securely to the concrete to prevent tipping when heavy loads are placed on the upper levels.

The most expensive real estate in your warehouse is the floor. The cheapest space is the air. If you aren't building up, you are losing money.

Modern fire codes and forklift capabilities are the only limits to how high you can go. High-bay racking shelves for warehouse systems can triple your storage capacity without expanding your building's footprint.

However, going higher often means you need to rethink your aisles. Standard aisles are usually 12 feet wide. If you switch to narrow aisle (NA) or very narrow aisle (VNA) racking, you can shrink that down significantly.

VNA systems allow you to pack more racking shelves for warehouse rows into the same room. The trade-off is equipment. You will need specialized turret trucks or order pickers that can operate in tight spaces. You can't just use a standard counterbalance forklift in a 6-foot aisle.

Safety is not an optional add-on. When you are storing thousands of pounds of product above people's heads, structural integrity is everything.

Always check the seismic rating of the racking shelves for warehouse systems you are considering. Even if you aren't in a high-risk earthquake zone, seismic ratings ensure the racks can withstand vibrations and minor impacts.

Pay close attention to the beam capacity. It is easy to overload a shelf if your team isn't paying attention. Label every beam clearly with its maximum load limit.

Wire decking is another essential safety component for racking shelves for warehouse installations. It prevents loose boxes or broken pallets from falling through the beams and injuring someone below. It also allows water from overhead sprinklers to reach the lower levels during a fire, which is often a requirement for insurance and fire marshals.

Every warehouse manager faces this dilemma: should you buy brand new equipment or look for used racking shelves for warehouse deals?

Used racking can save you 30% to 50% upfront. This is a massive chunk of change. However, it comes with risks. You might not know the history of the steel. Has it been overloaded? Is there structural fatigue that isn't visible to the naked eye?

If you go the used route, demand an inspection. Look for rusted baseplates, bent cross-bracing, or repainted sections that might be hiding damage.

New racking shelves for warehouse units come with manufacturer warranties and engineering data. You know exactly what the load limits are. For large, high-bay projects, new is almost always the safer bet. For smaller, ground-level storage, used might be a smart financial move.

Installing the racks is only half the battle. You need to arrange them in a way that makes sense for your pickers.

Your racking shelves for warehouse layout should minimize travel time. Place your fastest-moving items (A-movers) in the most accessible locations, usually at waist height and near the shipping docks. Slower items (C-movers) can go on the higher shelves or in the back of the facility.

Consider the direction of flow. You don't want forklifts crossing paths constantly. One-way aisles can reduce accidents and speed up the retrieval process. The design of your racking shelves for warehouse floor plan dictates the efficiency of your entire workforce.

Warehouses are dynamic environments. Your needs today won't be your needs five years from now.

Look for modular racking shelves for warehouse designs. You want a system where beams can be easily adjusted without welding or cutting. As your product packaging changes, you might need to lower or raise shelf heights.

Tear-drop style pallet racking is the industry standard in many regions because it is interchangeable and easy to adjust. If you buy a proprietary style of racking shelves for warehouse that is hard to find, you will struggle to find replacement parts or expansion components later.

You might have a maintenance team that is handy with tools, but installing heavy-duty industrial racking is a specialized skill.

Improper anchoring is a leading cause of rack collapse. The baseplates must be anchored into the concrete slab with specific torque settings. The uprights must be perfectly plumb. If a racking shelves for warehouse tower is leaning even a fraction of an inch, the weight distribution shifts, and the capacity drops drastically.

Hiring professional installers ensures that your setup meets local building codes and OSHA standards. They will also handle the permitting process, which is often required for tall racking shelves for warehouse structures.

Once your racks are up, the work isn't done. Forklifts will bump uprights. Pallets will slam into beams. Over time, this wear and tear compromises safety.

Establish a monthly inspection routine. Walk the aisles and look for any deformation in the metal. If a vertical column is bent, it needs to be unloaded and replaced immediately.

Repair kits are available for racking shelves for warehouse uprights, allowing you to bolt on a new leg section without replacing the entire frame. This is cost-effective, but it must be done by a professional. Never ignore a dented rack.

Your storage system is the skeleton of your business. If it is weak or disorganized, the rest of the body can't function properly.

Taking the time to choose the right racking shelves for warehouse application will pay dividends for years. It speeds up shipping times, reduces product damage, and keeps your employees safe.

Don't just buy shelves; invest in a solution. Analyze your data, measure your space, and pick a system that handles your current reality while leaving room for future growth.

A1: The most common type is Selective Pallet Racking. It is popular because it is cost-effective and provides immediate access to every single pallet without having to move other pallets first. It works well for warehouses that handle a wide variety of products (SKUs) and need flexibility.

A2: There is no single answer, as it depends on the beam size, steel gauge, and engineering. However, a standard pair of beams on heavy-duty racking shelves for warehouse systems can typically support between 2,000 lbs to 6,000 lbs per level. You must always check the manufacturer’s load capacity labels (load plaques) specific to your installation.

A3: It depends on your forklift equipment. A standard counterbalanced forklift usually requires aisles that are 12 to 14 feet wide. If you use Reach Trucks, you can reduce aisles to about 8 to 9 feet. For Very Narrow Aisle (VNA) systems using turret trucks, aisles can be as narrow as 5 to 6 feet to maximize the space for racking shelves for warehouse storage.

A4: Generally, it is not recommended. While many systems use a "teardrop" connection style that looks similar, slight differences in manufacturing tolerances can lead to safety issues. Mixing brands can also void warranties. It is best to stick to one manufacturer for your racking shelves for warehouse to ensure structural integrity and proper locking connections.

A5: In most municipalities, yes. Because high-pile storage creates safety and fire risks, you usually need a building permit. The city will verify that your racking shelves for warehouse plan meets seismic codes, fire suppression (sprinkler) requirements, and egress paths for worker safety. Always check with your local building department before installation.

Wechat

Wechat

Whatsapp

Whatsapp