In the field of warehousing and logistics, the choice of racking directly impacts warehouse space utilization, storage and retrieval efficiency, and operating costs. Narrow aisle racking, as a highly efficient storage solution, has recently gained favor among many companies. By optimizing aisle widths, it achieves higher storage density within limited space, but it also has some limitations. This article will analyze the advantages and disadvantages of narrow aisle racking from multiple perspectives to help readers better understand this storage method.

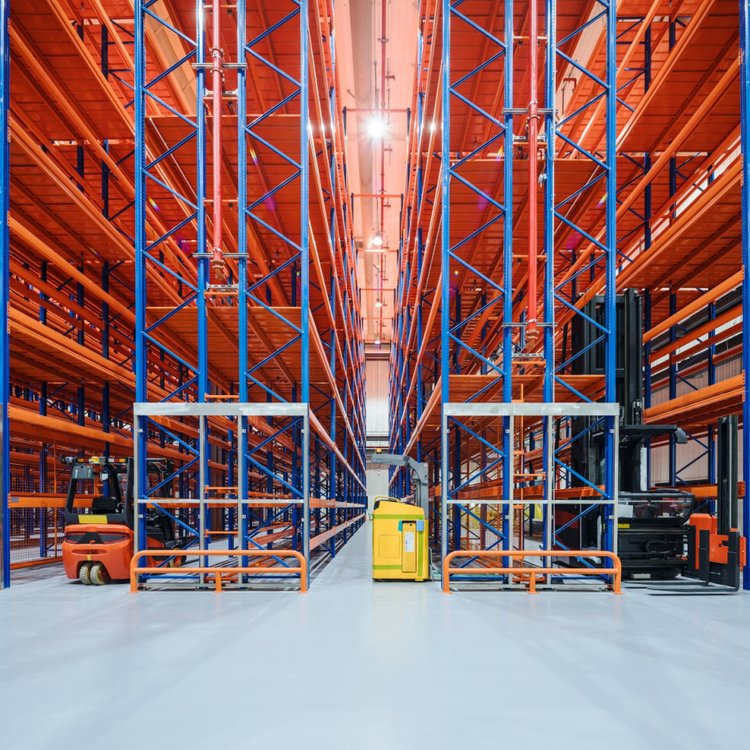

Narrow aisle racking differs from traditional heavy-duty racking in its innovative design, featuring narrower aisle widths, typically between 1.6 and 2 meters, compared to the aisle widths of conventional racking, which are typically over 3 meters. This design significantly improves warehouse space utilization and is particularly suitable for warehouses with large storage volumes but limited available space.

Narrow aisle racking is often used in conjunction with specialized narrow aisle forklifts (such as three-way forklifts or rotary forklifts). These forklifts can maneuver flexibly in confined spaces, ensuring efficient storage and retrieval of goods. The height of the racks can also be adjusted to meet warehouse needs, with some even exceeding 10 meters to fully utilize vertical space.

The core advantage of narrow aisle racking is space saving. Due to the reduced aisle width, a warehouse of the same area can accommodate more cargo spaces. For example, in a traditional racking system, aisles may occupy about 40% of the total warehouse area, while narrow aisle racking can reduce this proportion to 20%-30%, significantly improving storage capacity.

In urban warehousing environments where every inch of land is valuable, storage density is crucial. Narrow aisle racking increases the number of cargo spaces per unit area by reducing the number of aisles. It is particularly suitable for storing goods with a large number of SKUs but a moderate inventory of a single product, such as e-commerce warehousing, food and beverage industries, etc.

Although narrow aisle racks have narrow aisles, access efficiency is not reduced when used with dedicated forklift equipment. Equipment such as three-way forklifts can operate flexibly in narrow spaces, reducing the time required for forklifts to turn and adjust, thereby improving overall operational efficiency.

Narrow aisle racking requires specialized forklift equipment, such as a three-way forklift or a rotary forklift, which is usually much more expensive than a regular forklift. Due to the narrow aisles, the forklift driver's operating skills are more demanding, and additional training costs may be required.

Narrow aisle racking has narrow aisles, so the flatness of the warehouse floor is more demanding. If the floor is uneven, it may cause the forklift to operate unsteadily and even affect the safety of the racking. If there are many columns or obstacles in the warehouse, it may also affect the layout of the narrow aisle racking.

Narrow-aisle racking is a highly efficient warehousing solution that significantly improves space utilization and storage density, making it particularly suitable for businesses with limited space but high storage needs. However, its high equipment costs, strict warehouse requirements, and limited flexibility mean it's not suitable for all businesses.

When selecting a racking system, businesses should comprehensively evaluate the suitability of narrow-aisle racking based on their business characteristics, budget, and future development needs. Only by finding the solution that best suits their warehousing needs can they truly achieve the goal of reducing costs and increasing efficiency.

Wechat

Wechat

Whatsapp

Whatsapp