For businesses looking to optimize their warehouse storage, selecting the right racking system is a critical decision. While steel has traditionally dominated the market, aluminum pallet rack systems are emerging as a superior solution for many applications. This guide explores everything you need to know about this versatile storage option.

If you manage inventory in environments where weight, corrosion, or cleanliness is a concern, an aluminum pallet rack could be the perfect fit. Let's dive into the specifics.

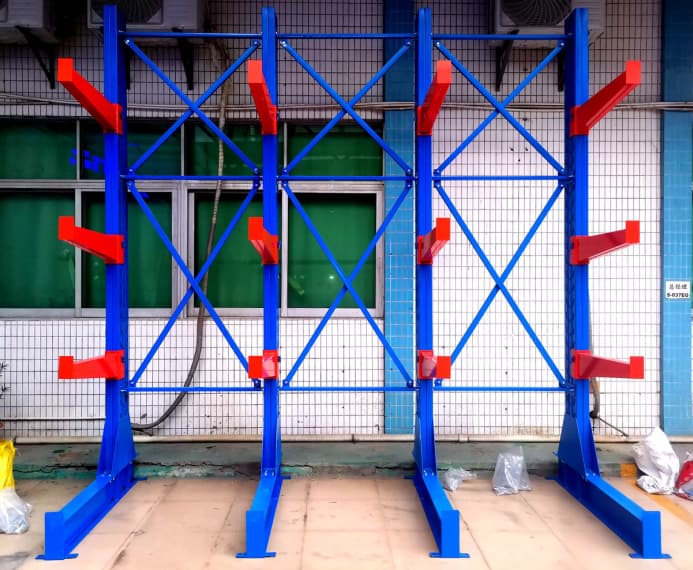

An aluminum pallet rack is a storage system designed to hold materials on pallets. Unlike traditional steel racks, its main structural components are fabricated from high-strength aluminum alloy.

These systems typically feature a bolt-free, riveted design. This makes assembly straightforward without needing specialized tools. The core components include upright frames, beams, and safety locks.

The design prioritizes a high strength-to-weight ratio. This means aluminum racking offers significant durability without the heaviness of steel. It is engineered for efficient storage and easy reconfiguration.

Choosing aluminum pallet racking comes with a distinct set of benefits. These advantages address common pain points in logistics and storage management.

Lightweight and Easy Installation

The most obvious benefit is weight. Aluminum storage racks are significantly lighter than their steel counterparts. This makes them easier to handle and install.

A small team can often assemble an entire system manually. No need for heavy machinery like forklifts just for setup. This reduces installation time and costs.

Superior Corrosion Resistance

Aluminum pallet racking naturally resists rust and corrosion. This is a game-changer for certain environments. It performs exceptionally well in cold storage, food processing, and pharmaceutical warehousing.

These industries often face moisture, condensation, or chemical exposure. An aluminum rack maintains its integrity and appearance where steel would degrade. This leads to a longer operational lifespan with less maintenance.

Hygienic and Easy to Clean

The non-porous surface of aluminum is easy to keep clean. It does not harbor bacteria or pests. This makes aluminum warehouse racks ideal for industries with strict hygiene standards.

A simple wipe-down is often all that's needed. There's no risk of paint chipping or rust contaminating products. This supports compliance with regulations like FDA or HACCP.

Durability and Strength

Don't let the light weight fool you. High-grade alloy aluminum pallet racks are built to last. They are designed to handle substantial dynamic and static loads.

The material does not become brittle in freezing temperatures. This makes it a reliable choice for freezer applications. Its durability ensures a strong return on investment over many years.

Understanding where aluminum racking systems shine helps in making an informed purchase. They are not always a one-for-one replacement for steel, but are optimal in specific settings.

Cold Storage and Freezer Warehouses

This is perhaps the perfect application. The combination of corrosion resistance and cold-temperature durability is unmatched. Aluminum racks for cold storage prevent ice buildup issues common with steel.

They also handle the thermal contraction and expansion of daily freeze-thaw cycles better. This maintains structural safety and load capacity over time.

Food and Beverage Industry

From dry storage to processing areas, hygiene is paramount. Aluminum pallet racking meets stringent sanitary requirements. It is also resistant to many cleaning agents used in these facilities.

Pharmaceutical and Medical Supply Storage

Cleanrooms and medical storage demand contaminant-free environments. The easy-to-clean nature of aluminum storage racks makes them a preferred choice. They help maintain the purity of sensitive products.

Portable and Temporary Storage Needs

The lightweight nature makes aluminum racks highly portable. They are excellent for trade shows, temporary warehouses, or seasonal storage. They can be dismantled and relocated with minimal effort.

When deciding on a storage system, a direct comparison is useful. Each material has its place based on operational needs.

Weight and Handling

Aluminum pallet racks are about one-third the weight of steel racks. This simplifies logistics, installation, and any future layout changes. Steel is heavier and generally requires equipment to move.

Corrosion Resistance

Aluminum wins decisively here. It forms a protective oxide layer when exposed to air. Steel requires galvanization or paint coatings, which can scratch and chip, leading to rust.

Cost Considerations

The initial purchase price for aluminum pallet racking can be higher than basic steel racking. However, the total cost of ownership often favors aluminum in suitable environments. Factors like longevity in corrosive settings, zero maintenance, and no need for repainting balance the scales.

Load Capacity

High-quality steel racking can generally support higher ultimate load capacities for heavy-duty industrial applications. However, modern aluminum rack systems are more than capable of handling standard pallet loads up to several thousand pounds per level, suiting the vast majority of warehouse needs.

Not all aluminum pallet rack systems are created equal. Pay attention to these features when selecting a supplier.

Alloy Quality and Construction

Seek out racks made from high-grade, industrial aluminum alloy (like 6000-series). The construction should be robust, with reinforced connections. Look for a clean, welded finish on frames.

Beam Design and Safety

Beams should have a secure safety lock mechanism that prevents accidental dislodging. A step-beam design can offer easier pallet placement. Ensure the beam capacity matches your inventory weight.

Adjustability

A key feature of good pallet racking is flexibility. Look for systems with easy-to-adjust beam heights. This allows you to adapt to changing pallet sizes and optimize vertical space.

Compliance and Certification

Reputable systems will be designed to meet relevant industry standards. While specific codes vary by region, look for manufacturers who engineer their aluminum racks to recognized structural load and safety guidelines.

While low-maintenance, proper care ensures the longevity and safety of your aluminum warehouse racks.

Regular Inspections

Conduct routine visual inspections. Look for any signs of damage, such as dents or bends, especially after an impact. Check that all safety locks are fully engaged.

Loading Practices

Always adhere to the rated load capacity. Distribute weight evenly across the beams. Never overload a rack, as it can compromise the entire structure's integrity.

Cleaning

For general cleaning, use mild soap and water. Avoid abrasive cleaners or tools that could scratch the surface. In corrosive environments, rinse racks periodically if exposed to salts or harsh chemicals.

Professional Assessment

Have your aluminum pallet racking system assessed by a professional periodically. They can check for alignment issues and ensure it continues to meet safety standards as your use evolves.

Q1: Are aluminum pallet racks as strong as steel racks?

A1: For standard warehouse applications, high-quality aluminum pallet racks are exceptionally strong and fully capable of handling typical palletized loads. They are engineered with a high strength-to-weight ratio. While the absolute maximum load capacity of heavy-duty steel might be higher, aluminum racks meet or exceed the requirements for most industries, especially where corrosion resistance is a priority.

Q2: Can I use aluminum pallet racking in a standard warehouse?

A2: Absolutely. Aluminum pallet racking is an excellent choice for standard warehouses. Its benefits like lightweight installation, ease of reconfiguration, and hygiene are valuable in any setting. The decision often comes down to specific needs like budget, potential for moisture, or future plans for the space.

Q3: How do I clean and maintain my aluminum racks?

A3: Maintenance is simple. Wipe down the racks regularly with a soft cloth and a mild, non-abrasive cleaner diluted in water. Avoid harsh chemicals or steel wool. The primary maintenance involves routine visual safety inspections to check for damage and ensure all connectors are secure.

Q4: Are aluminum racks more expensive than steel?

A4: The initial purchase price for aluminum pallet racking is often higher than entry-level steel racking. However, considering the total cost of ownership—including no need for anti-rust treatments, longer lifespan in corrosive environments, and lower handling/installation costs—aluminum can be a more cost-effective solution over time.

Q5: Can the racks be easily reconfigured or moved?

A5: Yes, one of the standout features of aluminum pallet racking is its easy reconfigurability. Their lightweight and typically bolt-free, riveted design allow a team to dismantle, relocate, and reassemble sections quickly without specialized tools. This offers fantastic flexibility for changing warehouse layouts.

Wechat

Wechat

Whatsapp

Whatsapp