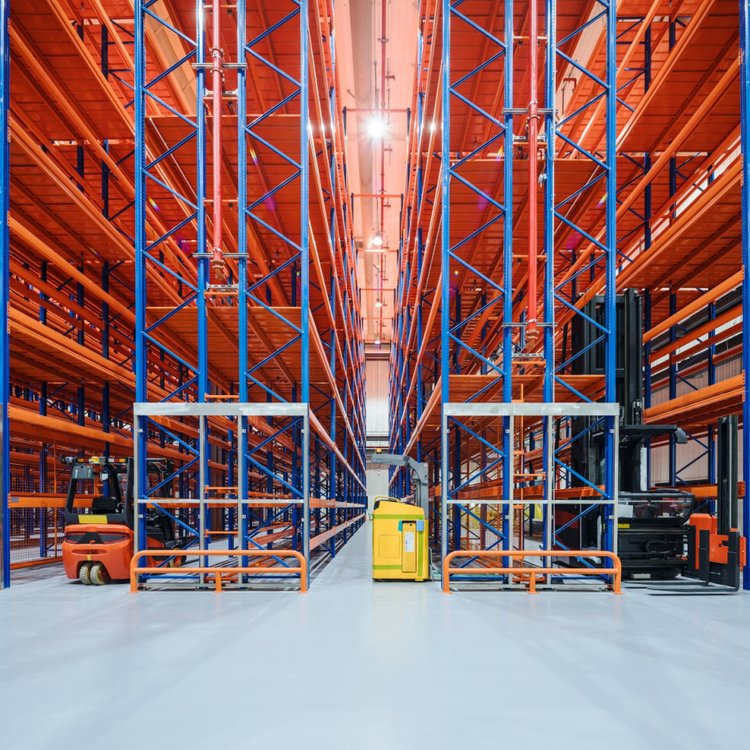

When it comes to optimizing warehouse storage, investing in new pallet racking is a crucial decision for businesses of all sizes. However, one of the most common questions that arise is, "What factors influence new pallet racking prices?" Understanding these prices is essential for budgeting and making informed purchasing decisions. In this article, we will delve into the various aspects that affect new pallet racking prices, providing you with a comprehensive overview to help you navigate the market. Whether you're a small business owner or a logistics manager, knowing what drives these costs can save you money and ensure you get the best value for your investment. We'll cover key elements such as material types, system designs, installation expenses, supplier comparisons, and long-term benefits. By the end, you'll have a clear picture of what to expect when researching new pallet racking prices.

New pallet racking prices are not one-size-fits-all; they vary based on several critical factors. First and foremost, the material used in construction plays a significant role. Most pallet racking systems are made from steel, but the grade and thickness can differ, affecting both durability and cost. For instance, high-strength steel racking tends to be more expensive but offers better load-bearing capacity and longevity. Additionally, the size and dimensions of the racking—such as height, width, and depth—directly impact new pallet racking prices. Customized configurations for unique warehouse layouts often come at a premium compared to standard off-the-shelf options.

Another factor is the type of racking system. Selective pallet racking, which allows easy access to each pallet, is generally more affordable than specialized systems like drive-in or push-back racking. The latter involves complex mechanisms that increase manufacturing costs. Furthermore, brand reputation and quality certifications can sway new pallet racking prices. Established brands with proven safety records might charge more, but they often provide better warranties and customer support. Economic factors, such as raw material costs and supply chain disruptions, also cause fluctuations in new pallet racking prices. By considering these elements, you can better estimate your budget and avoid unexpected expenses.

The variety of pallet racking systems available on the market means that new pallet racking prices can range widely. Selective pallet racking is the most common and cost-effective option, with prices typically starting from $100 to $300 per bay, depending on capacity and size. This system is ideal for warehouses that need frequent access to a diverse range of products. In contrast, drive-in racking systems, which maximize storage density by allowing forklifts to drive into the structure, are more expensive due to their complex design. Prices for drive-in systems can range from $200 to $500 per bay, making them a significant investment for high-density storage needs.

Push-back racking is another popular choice, featuring dynamic lanes that allow pallets to be stored deeper. New pallet racking prices for push-back systems often fall between $150 and $400 per bay, offering a balance between accessibility and space utilization. For heavy-duty applications, pallet flow racking, which uses gravity rollers to move pallets, can cost $300 to $600 per bay. It's crucial to assess your inventory turnover and storage requirements when comparing these new pallet racking prices. By understanding the pros and cons of each system, you can select one that aligns with your operational needs and budget constraints.

When budgeting for new pallet racking, it's essential to account for installation costs, which can significantly affect overall new pallet racking prices. Professional installation ensures safety and compliance with industry standards, but it adds to the total expense. On average, installation fees range from $500 to $2,000 or more, depending on the complexity of the system and the size of the warehouse. For instance, a simple selective racking setup might be quicker to install, whereas a multi-level mezzanine integration could require specialized labor and equipment, driving up costs.

Beyond installation, other expenses include delivery charges, which vary based on location and order size, and potential site preparation costs like floor leveling or reinforcing. Maintenance and accessories—such as safety locks, decking, and column guards—also contribute to new pallet racking prices. These add-ons enhance functionality and safety but can increase the initial investment by 10-20%. It's wise to request detailed quotes from suppliers that break down all these components. This way, you can avoid hidden costs and ensure that your new pallet racking prices reflect a complete package, including any necessary post-purchase support.

Shopping around for suppliers is a key step in finding competitive new pallet racking prices. Different vendors offer varying rates based on their sourcing, production methods, and profit margins. Online marketplaces and direct manufacturers often provide lower prices due to reduced overhead, but it's important to verify their credibility and product quality. For example, some suppliers might advertise low new pallet racking prices but use subpar materials, leading to higher long-term costs from repairs or replacements.

To make an informed decision, obtain multiple quotes and compare them side-by-side. Look for suppliers who offer transparent pricing, including details on warranties, lead times, and customer reviews. Bulk purchases can also reduce new pallet racking prices, as many suppliers provide discounts for large orders. Additionally, consider the supplier's location—local companies might charge less for shipping and offer faster service. Don't forget to factor in after-sales support, such as installation services and maintenance packages, which can add value beyond the initial new pallet racking prices. By conducting thorough research, you can secure a deal that balances cost with quality and reliability.

While upfront new pallet racking prices are important, evaluating the long-term value and return on investment (ROI) is equally crucial. High-quality racking systems may have higher initial costs but can last for decades with proper maintenance, reducing the need for frequent replacements. This durability translates into lower total cost of ownership, making it a wise financial decision. Moreover, efficient racking improves warehouse operations by increasing storage capacity and streamlining workflows, which can boost productivity and reduce labor costs.

To assess ROI, calculate how the new pallet racking prices compare to potential savings in space utilization, inventory management, and safety improvements. For instance, a well-organized racking system can minimize product damage and accidents, leading to lower insurance premiums. Energy-efficient designs might also contribute to cost savings over time. When reviewing new pallet racking prices, consider the system's scalability—can it be easily expanded as your business grows? Investing in a flexible solution might have a higher price tag initially but offer better adaptability, ensuring that your racking remains cost-effective in the long run. Ultimately, focusing on value rather than just price will help you maximize your investment.

Q1: What is the average cost range for new pallet racking systems?

A1: The average new pallet racking prices vary based on the system type and specifications. For selective pallet racking, costs typically range from $100 to $300 per bay, while specialized systems like drive-in or push-back racking can cost $200 to $600 per bay. Factors such as material quality, customization, and supplier discounts also influence the final price.

Q2: How can I reduce new pallet racking prices without compromising quality?

A2: To lower new pallet racking prices, consider purchasing in bulk, comparing quotes from multiple suppliers, and opting for standard configurations instead of custom designs. You can also look for seasonal promotions or used components, but ensure they meet safety standards. Additionally, focusing on energy-efficient and durable materials can reduce long-term costs.

Q3: Are there hidden costs associated with new pallet racking prices?

A3: Yes, hidden costs can include installation fees, delivery charges, site preparation expenses, and add-ons like safety accessories. It's important to request detailed quotes from suppliers that outline all potential costs to avoid surprises. Regular maintenance and potential upgrades should also be factored into your budget.

Q4: How do economic factors affect new pallet racking prices?

A4: Economic factors such as fluctuations in steel prices, supply chain disruptions, and inflation can cause new pallet racking prices to rise or fall. For example, increased demand for raw materials or tariffs on imports might lead to higher costs. Staying informed about market trends can help you time your purchase for better deals.

Q5: What should I look for in a supplier when comparing new pallet racking prices?

A5: When comparing suppliers, evaluate their reputation, product warranties, customer reviews, and after-sales support. Ensure they provide transparent new pallet racking prices without hidden fees. It's also beneficial to choose suppliers with experience in your industry, as they can offer tailored advice and reliable service.

In conclusion, understanding new pallet racking prices involves examining multiple factors, from material choices and system types to installation and long-term value. By taking a holistic approach, you can make a smart investment that enhances your warehouse efficiency and supports business growth. If you have more questions about new pallet racking prices, consult with industry experts to get personalized recommendations.

Wechat

Wechat

Whatsapp

Whatsapp