Understanding cantilever racking prices is a critical step for any business planning to store long, bulky, or awkward items. This storage solution is ideal for items like timber, pipes, furniture, or rolls of material.

The final price is not a single number. It is the sum of several variables unique to your operation. This guide breaks down the components and factors that determine cantilever racking prices.

We will explore what influences cost, how to budget accurately, and ways to manage your investment. Knowing these details helps you make an informed purchasing decision.

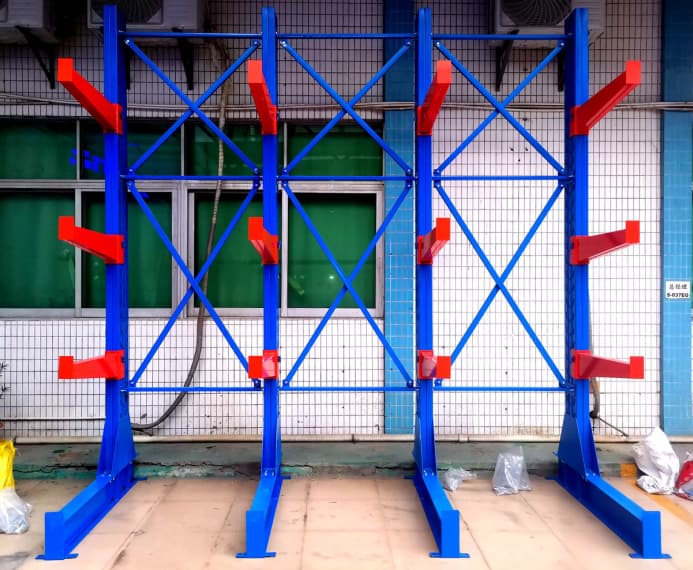

Before discussing cantilever racking prices, it helps to know the product. Cantilever racking is a free-standing storage system with vertical columns and horizontal arms.

The arms extend out to support loads without the obstruction of front columns. This design allows for easy side-loading of long items using a forklift or crane.

It is the preferred system for industries like lumber, metal, plastic, and construction. The open access greatly simplifies storage and retrieval of lengthy inventory.

Understanding its function clarifies why certain design choices directly impact overall cantilever racking prices.

The total cost is built from the price of individual parts. Each component contributes to the final quote for your cantilever racking system.

Upright Columns (Towers): These are the vertical supports. Prices vary based on column height, steel gauge (thickness), and load capacity. Taller, heavier-duty columns cost more.

Arms (Brackets): These are the horizontal supports that hold the inventory. Cantilever racking prices are heavily influenced by arm length, quantity, and capacity. Longer, stronger arms increase the cost.

Base Plates and Anchors: These secure the columns to the concrete floor. The type and size required for stability affect the bottom line.

Bracing and Connectors: Diagonal and horizontal braces add structural integrity. More bracing, or specialized bracing for high seismic zones, will raise cantilever racking prices.

Wire Decking or Supports: Optional decking between arms provides a shelf surface for smaller items. Adding this feature increases the total price.

Several project-specific factors cause cantilever racking prices to fluctuate from one quote to another. These are the main variables suppliers consider.

System Dimensions: The single biggest driver of cost. This includes total height, number of columns, and number of arm levels. A larger, taller system uses more material, increasing cantilever racking prices.

Required Load Capacity: How much weight each arm level must hold is crucial. Systems rated for 5,000 lbs per arm cost significantly more than those rated for 1,000 lbs. Heavier capacities require thicker steel and more robust construction.

Arm Length: Standard arm lengths might be 24, 30, or 36 inches. Custom, extra-long arms for oversized items will have a higher price per unit.

Material and Finish: Most cantilever racking is made from structural steel. Prices can vary with steel market rates. A powder-coated finish for corrosion resistance (important in certain environments) adds to the cost compared to plain primer.

Seismic and Safety Requirements: Facilities in regions with strict seismic codes need specially engineered systems. This additional engineering and reinforced design substantially impacts cantilever racking prices.

When budgeting, consider expenses beyond the base cantilever racking prices. These are often necessary for a complete, operational system.

Delivery and Freight: Cantilever racking is heavy and bulky. Shipping costs can be substantial, especially for large orders or remote locations. Always ask for a delivered price.

Professional Installation: While some companies install their own racks, professional installation is recommended. Certified installers ensure safety and compliance. Installation fees are typically separate from material cantilever racking prices.

Site Preparation: This may include floor marking, ensuring the concrete slab is level and strong enough, and clearing the installation area. These are usually the client's responsibility.

Permits and Engineering Stamps: Local building departments may require permit drawings sealed by a professional engineer. This service often carries an extra fee from your supplier or a third-party engineer.

Accessories: Add-ons like column protectors, end-of-aisle guards, safety pins, or special signage are not always included in basic cantilever racking prices.

To understand true cantilever racking prices, you must provide detailed information. Vague requests lead to inaccurate estimates.

Prepare your project specifications. Have clear data on item dimensions, weight per load, total inventory volume, and your available warehouse space (height, width, depth).

Request itemized quotes. A good quote will list prices for columns, arms, bases, and accessories separately. This allows for fair comparison between suppliers.

Ensure quotes include all necessary components. Verify that the quoted cantilever racking prices cover bracing, anchors, and any required decking.

Ask about lead times. A lower price might come with a very long production delay, which could disrupt your operations.

There are ways to control cantilever racking prices without compromising on safety or functionality. Smart planning can lead to significant savings.

Optimize Design for Density: Work with a designer to maximize storage within your space. Efficient use of height and arm spacing can reduce the number of columns needed, lowering overall cantilever racking prices.

Consider Standard Sizes: Custom arm lengths or column heights are more expensive. Where possible, design your system around the supplier's standard component sizes.

Evaluate Capacity Honestly: Do not over-specify. If your heaviest bundle weighs 3,000 lbs, you do not need arms rated for 5,000 lbs. Accurate load planning prevents paying for unnecessary strength.

Plan for Phased Installation: If budget is tight, consider a phased approach. Install part of the system now and add more columns and arms later as needed.

Prioritize Quality and Safety: The lowest cantilever racking prices can sometimes mean inferior materials or poor engineering. Always prioritize reputable suppliers who comply with relevant safety standards. A rack failure is far more costly than the initial investment.

Cantilever racking prices are determined by a combination of system size, strength, design, and ancillary services. A clear understanding of your storage needs is the first step to getting a fair and accurate cost.

Investing time in precise planning and gathering detailed quotes pays off. It ensures you get a system that fits both your operational requirements and your budget.

A well-chosen cantilever racking system improves warehouse efficiency and safety for years to come, making it a valuable long-term investment.

Q1: What is the approximate price range for a single cantilever racking bay?

A1: Cantilever racking prices per bay vary widely. A basic, single-column bay with two arms per side might start in the hundreds. A large, heavy-duty double-column bay can cost several thousand dollars. The total system price depends entirely on the number of bays and specifications.

Q2: Does installation cost extra, and how much is it?

A2: Yes, professional installation is typically a separate line item. Installation costs for cantilever racking can range from 20% to 35% of the total material price, depending on system complexity, site conditions, and labor rates in your area.

Q3: Are used cantilever racks a good way to save money?

A3: Used racks can offer lower cantilever racking prices, but caution is essential. You must verify the structural integrity, ensure components are not damaged, and confirm the dimensions and load ratings match your needs. Missing or incompatible parts can negate initial savings.

Q4: How do cantilever racking prices compare to pallet racking prices?

A4: Per linear foot of storage, cantilever racking prices are generally higher than standard selective pallet racking. This is due to its specialized design, heavier construction, and lower production volume. However, for long items, it is the only practical solution.

Q5: Can I get a price quote online, or do I need a site visit?

A5: Many suppliers can provide a preliminary estimate based on your detailed specifications (height, arm length, capacity, quantity). However, for a final, firm quote—especially for large or complex projects—a professional site visit is often required to assess site-specific conditions.

Wechat

Wechat

Whatsapp

Whatsapp