If you're into indoor gardening, hydroponics, or urban farming, you've likely hit a common wall: space. Floor space is precious. The solution isn't always to find a bigger room; it's to think vertically. This is where the ingenuity of a pallet rack grow system shines.

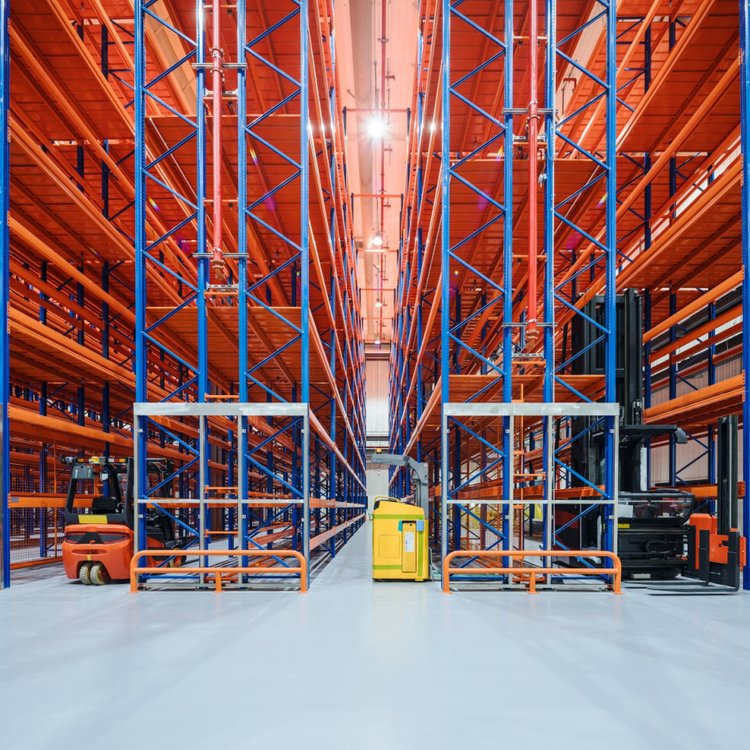

A pallet rack grow system is exactly what it sounds like. It involves repurposing or utilizing industrial-style steel pallet racking to create a strong, multi-tiered framework for growing plants. It’s a modular, heavy-duty answer to vertical farming at a scalable level.

This approach is gaining massive traction among hobbyists and commercial micro-greens growers alike. Why? Because it turns unused vertical air space into a prolific growing zone. Let's dig into how it works and why it might be your best growing decision.

At its core, a pallet rack grow system is a structural frame used to support multiple growing levels. Each level, or shelf, can hold grow trays, hydroponic channels, container plants, or a full hydroponics setup.

Unlike flimsy store-bought shelving, pallet racking is engineered to hold immense weight—thousands of pounds per level. This makes it perfectly safe for holding water-filled hydroponic reservoirs, heavy soil containers, and powerful grow lights.

The system is highly customizable. You decide the shelf height, the number of levels, and what growing method happens on each tier. It’s a blank canvas for cultivation.

Why go through the effort? The benefits of a vertical pallet rack garden are substantial and tangible.

Unmatched Space Efficiency

This is the primary driver. By growing vertically, you can multiply your grow area without increasing your footprint. A three-tier rack gardening system can effectively triple your production in the same floor space.

Heavy-Duty Capacity and Safety

Wire shelving bends. Particleboard sags with moisture. Steel pallet racking does neither. It’s designed for warehouse pallets, so it handles the weight of your operation with a huge safety margin. You can hang heavy lights and water systems without worry.

Total Customization and Flexibility

You can adjust beam heights as your plants grow or as you change crops. You can configure aisles for access. The modular nature means you can expand the system later by adding more uprights and beams.

Improved Organization and Workflow

Everything has a dedicated, organized place. Mother plants can be on top, propagation in the middle, and flowering plants below. This creates an efficient workflow for feeding, pruning, and harvesting.

Cost-Effectiveness in the Long Run

While the initial investment in new racking can be higher than cheap shelves, its durability is unbeatable. It won’t need replacing. Used pallet racking is also widely available, offering a very budget-friendly path to a professional-grade indoor farming structure.

Building a functional system requires more than just the rack. Here’s a breakdown of the essential components.

The Racking Structure

This is the skeleton. You’ll need vertical upright frames and horizontal load beams. Key specifications are upright height, beam length (shelf depth), and load capacity. Beams are typically adjustable in 1-3 inch increments.

Grow Lighting

Each tier needs its own light source. LED grow lights are the top choice for vertical rack farming due to their low heat output and energy efficiency. You'll need to mount them securely from the beam above each shelf, ensuring proper height adjustment.

Lighting Management

Timers or smart controllers are non-negotiable to automate your light cycles. This ensures consistency for plant health and frees you from daily manual switching.

Growing Medium

This depends on your method. It could be hydroponic net pots with clay pebbles, soil in fabric pots, coco coir, or channels for nutrient film technique (NFT). The pallet rack grow system accommodates them all.

Environmental Control

With multiple lights on, temperature and humidity management is critical. You will likely need inline exhaust fans, circulation fans, and possibly a dehumidifier. The open frame of the rack actually aids in air circulation around plants.

Trays and Drainage

Water containment is a must. Use heavy-duty plastic trays or DIY lined troughs on each shelf to catch runoff from watering or any potential leaks from hydroponic systems. This protects your floor and allows for runoff management.

Planning prevents poor performance. Think through these points before assembling.

Choosing the Right Racking Size

Measure your room first. Leave ample space for you to walk and work comfortably. Standard beam lengths are 4, 5, or 6 feet. Choose a height that fits your room while allowing space for top lighting and clearance.

Weight Distribution and Load Planning

Calculate the approximate weight on each shelf: plants, saturated medium, water reservoirs, and lighting. Ensure your chosen rack’s capacity per level exceeds this number. Always distribute weight evenly.

Light Spacing and Heat Management

Position lights to provide even coverage for the shelf below. Maintain the manufacturer’s recommended distance from the plant canopy. The biggest challenge in a multi-tier rack grow setup is heat rising from lower levels. Strong vertical air movement is key to dissipating it.

Access and Ergonomics

Don’t make shelves so deep that you can’t reach the plants at the back. Consider creating a “roll-under” space if using deep racks, allowing you to slide in for easy access to all plants.

Water and Electrical Logistics

Plan your water source and drainage paths. Drip trays need to be emptied. For electricity, use quality power strips and grounded outlets. Route cords safely along the frame to avoid tripping hazards and water exposure.

Not every plant is suited for this environment. These thrive:

Leafy Greens and Herbs

Lettuce, kale, spinach, basil, and mint are perfect. They have relatively low light needs and compact size, allowing for closer shelf spacing.

Microgreens and Sprouts

The quintessential commercial use for a pallet rack grow system. Each shelf becomes a production unit for rapid, high-density crops.

Strawberries

Excellent for vertical hydroponic or wicking bed systems on racks. They love the consistent environment and produce well.

Starter Plants and Clones

Use one tier as a dedicated, climate-controlled propagation station for seedlings and cuttings before they move to a main grow area.

What to Avoid

Tall, vining, or sprawling plants like full-sized tomatoes, corn, or pumpkins are generally not suitable due to height restrictions and light requirements.

A well-organized system makes maintenance smoother.

Create a daily checklist: check pH/EC (for hydroponics), monitor plant health, and ensure environmental controls are functioning.

Weekly tasks include refilling reservoirs, pruning, and cleaning debris from drip trays to prevent pests and mold.

Periodically, inspect the rack structure for tight connections and check all electrical connections for safety.

A pallet rack grow system is more than a set of shelves; it’s a paradigm shift in how we approach indoor cultivation. It offers a professional, scalable, and incredibly efficient method to maximize yield per square foot.

Whether you’re a hobbyist wanting a serious home garden or a small-scale commercial grower, the durability and flexibility of this approach are hard to beat. With careful planning around weight, light, and environment, you can build a vertical grow rack that produces bountiful harvests for years to come.

It turns the challenge of limited space into your greatest asset.

Q1: Is used pallet racking safe for a grow room?

A1: Yes, used pallet racking is generally very safe if it’s in good condition. Inspect it thoroughly for significant rust, cracks, or bent components. Ensure you have all necessary parts (beams, connectors, safety locks). It’s a cost-effective way to build a robust pallet rack grow system.

Q2: How many grow lights do I need per shelf?

A2: It depends entirely on the light’s footprint and your plants’ needs. Generally, you want to achieve full, even light coverage across the entire shelf area. For a 4x4 foot shelf, you might use one large LED fixture or multiple smaller ones. Always follow the manufacturer’s coverage guidelines.

Q3: How do I handle runoff water on upper shelves?

A3: This is a crucial detail. Each shelf must have a waterproof tray to catch runoff. For drainage, you can use small, gentle-sloping trays that drain to one corner via a tube, directing water to a floor-level collection reservoir or drain. Never let water drip freely from an upper shelf.

Q4: Can I use this for a soil-based garden, or is it only for hydroponics?

A4: Absolutely. A pallet rack grow system works excellently for soil or soilless mixes in containers or fabric pots. The key advantage is the strong support and organization. Ensure your drip trays are deep enough to handle soil runoff.

Q5: What’s the typical cost range for setting up a basic 3-tier system?

A5: Costs vary widely. Using used racking, you might spend $200-$500 on the structure. New racking can be double or triple that. Lighting is the biggest variable—a basic 3-tier setup with decent LEDs could range from $600 to $2000+ total, excluding environmental controls like fans and humidifiers. It’s an investment, but its durability provides long-term value.

Wechat

Wechat

Whatsapp

Whatsapp