Working in a warehouse or storage facility means facing high shelves daily. Manually handling pallets at elevation is slow, risky, and inefficient. This is where a pallet rack lifter becomes an essential tool.

A pallet rack lifter is a material handling device designed to safely and efficiently place or remove loaded pallets from storage racking. It empowers a single operator to manage inventory at height without needing a full forklift.

This article breaks down what you need to know about these devices. We’ll explore the main types, critical applications, and what to consider before buying one.

A pallet rack lifter is a motorized or hydraulic platform that raises and lowers loads within the vertical beams of storage racks. The operator typically walks alongside the machine, controlling it via a pendant or handle-mounted controls.

Unlike a forklift, a pallet rack access lifter does not require a driving operator or extensive aisle space. It slides directly into the rack structure. Its primary goal is to make manual pallet handling at height obsolete.

This equipment significantly enhances safety and productivity in picking and stocking operations.

Not all rack lifting needs are the same. Choosing the right type depends on your racking design and workflow.

Manual Hydraulic Pallet Rack Lifters

These are the most basic and cost-effective models. They use a hand-pumped hydraulic system to raise the platform. Lowering is controlled by a valve.

They are simple, reliable, and require no power source. However, they demand more physical effort from the operator, especially for frequent use or very heavy loads.

Electric/Battery-Powered Pallet Rack Lifters

These are the most popular type for regular use. An electric motor powered by a rechargeable battery handles the lifting and lowering.

Operation is effortless via push-button controls. They offer consistent performance, reduce operator fatigue, and are ideal for high-volume warehouses. Battery-powered pallet rack lifters provide excellent mobility.

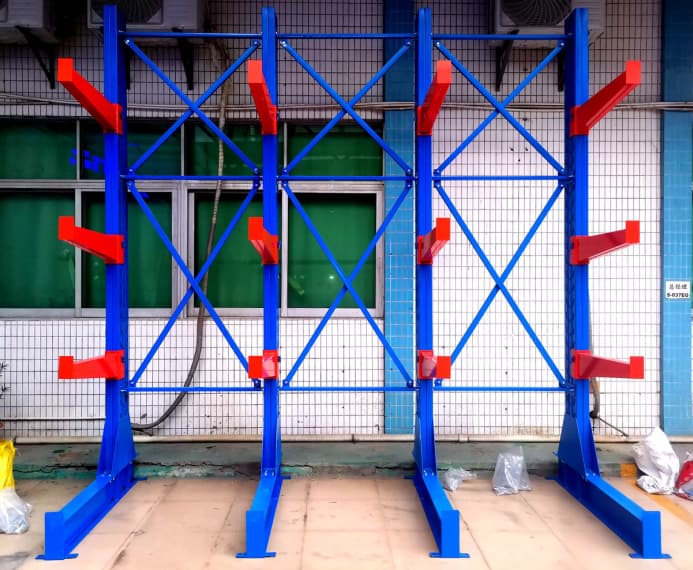

Straddle Walkie Pallet Rack Lifters

This design features outrigger arms or forks that straddle the base of the rack structure. This provides exceptional stability for very tall lifts or heavier capacities.

The straddle rack lifter is a robust choice for industrial environments with high-density storage and substantial loads.

Key Applications and Uses

The pallet rack lifter is versatile. Its main job is to bridge the gap between floor-level pallet jacks and high-level storage racks.

Order Picking and Case Picking

Operators can raise themselves and their picking containers to the exact product level. This allows for safe, accurate, and faster piece-picking or full-case picking from pallet racks.

Pallet Put-away and Retrieval

The core function. A single worker can safely store a loaded pallet onto a high beam or retrieve it for shipping, without waiting for a forklift or using unsafe ladders.

Inventory Management and Cycle Counting

Performing accurate counts is easier and safer. The operator can access every pallet face-to-face to check labels and quantities without guesswork.

Load Rearrangement and Consolidation

A pallet rack lifter allows operators to easily adjust pallet positions within a bay, combine partial loads, or rotate stock following FIFO principles.

Selecting the wrong equipment can lead to safety issues or poor performance. Here are the critical specs to evaluate.

Lifting Capacity and Platform Size

Capacity is paramount. You must know the maximum weight of your typical loaded pallet. Choose a pallet rack lifter with a capacity that exceeds this weight to include a safety margin.

Platform size must accommodate your pallet dimensions and provide safe standing space for the operator.

Lift Height and Lowered Height

Measure your highest storage beam. The lift height must exceed this. Also, check the machine’s collapsed height—it must fit under the lowest beam you need to access.

Power Source and Runtime

For electric models, consider battery voltage, amp-hour rating, and charging time. Ensure the runtime matches your shift patterns. Hydraulic models eliminate battery concerns but increase manual labor.

Maneuverability and Dimensions

The machine must fit comfortably within your rack aisles. Check its width against your aisle width. Swivel casters and a good turning radius are vital for tight spaces.

Safety Features

Never compromise on safety. Look for features like:

Maintenance and Durability

A pallet rack lifter is an investment. Look for robust construction from heavy-duty steel. Check service requirements and part availability. Simple, reliable designs often mean less downtime.

Cost vs. Value Analysis

While upfront cost is a factor, consider total value. A slightly more expensive, durable, and safer electric pallet rack lifter will pay for itself through increased productivity, reduced injury risk, and lower long-term costs compared to manual models or inefficient methods.

Even with the right equipment, proper use is non-negotiable.

Always inspect the pallet rack lifter before use. Check for damage, loose parts, and battery charge.

Ensure the load is centered, secure, and within the rated capacity. The operator must stay within the platform boundaries.

Wear appropriate personal protective equipment (PPE), like safety shoes.

Move smoothly and avoid sudden movements. Be aware of the environment, including floor conditions and overhead obstacles.

Never exceed the manufacturer’s rated load capacity or lift height. This is the most common cause of failure.

Follow a regular maintenance schedule as outlined in the user manual.

Integrating a pallet rack lifter into your warehouse operations is a straightforward decision for improving safety and efficiency. It removes the dangers of ladder use and the delays of waiting for forklifts.

By understanding the types available, matching the machine to your specific tasks, and prioritizing safety, you can select a pallet rack access lifter that delivers a strong return on investment. The right equipment empowers your team and optimizes your vertical storage space.

Q1: What is the typical weight capacity for a standard pallet rack lifter?

A1: Standard pallet rack lifter capacities range widely, from around 1,000 lbs (450 kg) for lighter-duty manual models to over 3,000 lbs (1,360 kg) for heavy-duty electric or straddle types. Always choose a capacity that exceeds your heaviest common load.

Q2: Can a pallet rack lifter be used with all types of storage racking?

A2: Most are designed for standard selective pallet racks. For drive-in, push-back, or other specialized racking, consult the manufacturer. Critical measurements are the inner clearance width between uprights and the beam height.

Q3: How much aisle space is needed to operate a pallet rack lifter?

A3: They require very little aisle space compared to forklifts. Typically, you only need enough width for the machine itself (often 36-48 inches) plus some room for the operator to walk beside it. This makes them ideal for narrow-aisle storage layouts.

Q4: What is the main difference between a manual hydraulic and an electric pallet rack lifter?

A4: The main difference is the power source and operator effort. A manual hydraulic pallet rack lifter requires the operator to pump a lever to raise the load, while an electric model uses a battery-powered motor for effortless, push-button lifting. Electric models are preferred for frequent use.

Q5: What regular maintenance does a pallet rack lifter require?

A5: Basic maintenance includes keeping the machine clean, regularly checking and tightening hardware, inspecting cables and hoses for wear, and lubricating moving parts as specified. For electric models, proper battery care and charger maintenance are essential. Always follow the detailed schedule in the operator’s manual.

Wechat

Wechat

Whatsapp

Whatsapp