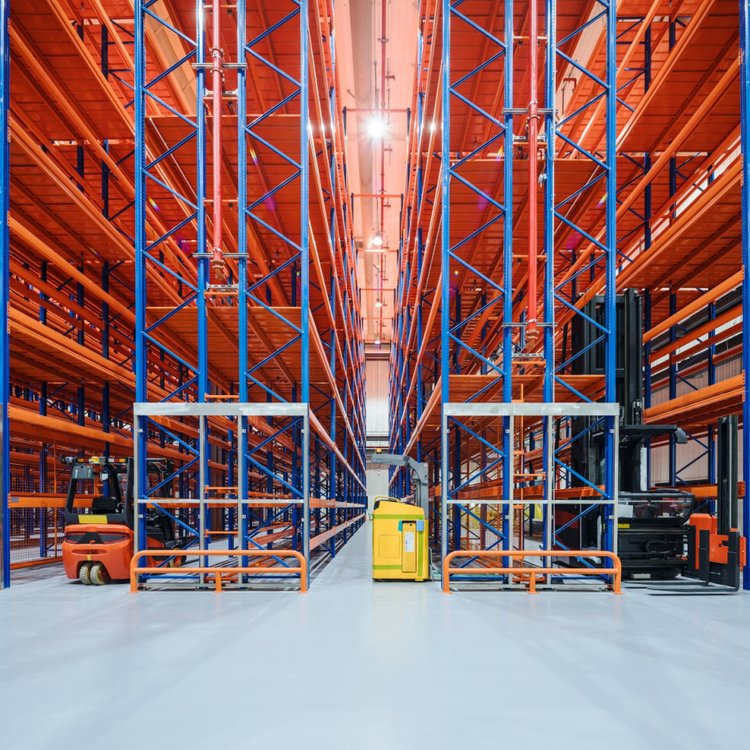

A well-planned warehouse racking layout design is the backbone of any successful logistics operation. It's the critical blueprint that dictates the flow of goods, the safety of personnel, and the overall productivity of your facility. An inefficient layout leads to wasted space, slower order picking times, increased labor costs, and potential safety hazards. Conversely, an optimized design can dramatically increase storage capacity, improve inventory accuracy, and accelerate order fulfillment.

This ultimate guide will walk you through the essential components of an effective layout, from the fundamentals of warehouse shelf design to the intricacies of warehouse rack installation. We will explore different types of warehouse rack systems and discuss the common pitfalls to avoid during the planning and implementation of your racking system in warehouse.

Before selecting a single beam or upright frame, it's crucial to understand the foundational principles that govern a successful layout. These principles ensure your design is not just a arrangement of metal, but a strategic asset.

Flow and Throughput: Your layout must facilitate a smooth, logical flow of goods from receiving to storage to shipping. Consider the paths for both inbound and outbound goods to minimize congestion and cross-traffic. The goal is to create a unidirectional flow that reduces travel time and handling.

Space Utilization: Maximizing cubic space is often more important than maximizing floor space. A good warehouse racking layout design looks upward, utilizing clear vertical height with appropriate high-bay racking systems, rather than just spreading out horizontally.

Product Characteristics: The size, weight, shape, and turnover rate (ABC analysis) of your inventory are the primary drivers of your storage solutions. Fast-moving items (A-items) should be placed in the most accessible locations, while slower-moving items (C-items) can be stored in higher or less accessible areas.

Accessibility and Selectivity: How quickly can you access a specific SKU? The balance between density and accessibility is key. Some systems offer high density but lower immediate access to all products (e.g., Drive-in racks), while others offer high selectivity but lower density (e.g., Selective pallet racks).

Scalability and Flexibility: Your business will change. A great layout design accommodates future growth, seasonal fluctuations, and changes in product mix. It should be modular and adaptable without requiring a complete overhaul.

The term warehouse shelf design often refers to the smaller, shelving units used for smaller parts, while warehouse rack typically describes larger systems for palletized goods. However, in practice, "racking" encompasses a broad spectrum of storage solutions. Your choice of system will fundamentally shape your layout.

1. Selective Pallet Rack

This is the most common and versatile type of racking system in warehouse operations. It consists of upright frames and horizontal beams, creating accessible aisles for forklifts. It offers excellent selectivity, meaning every pallet is immediately accessible. The width of the aisles is a critical part of the warehouse racking layout design, determined by the type of forklift (e.g., counterbalance vs. narrow-aisle reach trucks).

2. Drive-In/Drive-Through Rack

These systems are a high-density solution where forklifts drive directly into the rack structure to place and retrieve pallets. Drive-in racks have a single entrance, operating on a Last-In, First-Out (LIFO) basis. Drive-through racks have entries on both ends, allowing for First-In, First-Out (FIFO) inventory management. They are ideal for storing large quantities of a limited number of SKUs, such as cold storage facilities.

3. Push-Back Rack

Push-back racking is a dynamic system where pallets are stored on wheeled carts on slightly inclined rails. When a new pallet is loaded, it pushes the existing pallets back. When retrieving a pallet, the next one automatically rolls forward. It offers good density with better selectivity than drive-in racks and operates on a LIFO basis.

4. Pallet Flow (Dynamic) Rack

This high-density, high-throughput system uses gravity. Pallets are loaded on the high end of a slightly inclined track and flow forward on rollers to the unloading end. It's a perfect FIFO racking system in warehouse environments for perishable goods or products with expiration dates. It requires careful calculation of weight and speed for optimal performance.

5. Cantilever Rack

Designed for long, bulky, or irregularly shaped items like lumber, piping, or furniture, cantilever racks have arms that extend from a central column. This warehouse rack design provides unobstructed access to stored items, making it indispensable for specific industries.

6. Mezzanine Flooring

While not a rack itself, a mezzanine is a powerful tool in warehouse shelf design for creating additional level(s) within a facility. It’s perfect for housing smaller, non-palletized inventory on shelving units, creating office space, or housing packing stations, effectively doubling your usable floor space.

The terms warehouse rack installation and warehouse racking installation are interchangeable and refer to the physical assembly and erection of the storage systems. This is not a DIY project; it's a highly specialized task that demands precision and expertise.

Why Professional Installation is Non-Negotiable:

Safety: Improperly installed racking is a massive safety risk. It can lead to catastrophic collapses, causing injury, death, and massive product loss. Professional installers are trained to follow strict protocols and manufacturer specifications.

Structural Integrity: They ensure the rack is level, plumb, and all beams are securely locked with the correct connectors and torque settings. They also understand the critical importance of anchoring the system to the concrete floor to resist seismic and impact forces.

Compliance and Certification: Reputable installers ensure the final racking system in warehouse complies with all relevant local and international safety standards (e.g., OSHA, SEMA, RMI). They provide certification that the installation has been completed correctly, which is often required for insurance purposes.

Efficiency: Experienced crews can install a large system quickly and correctly, minimizing disruption to your ongoing operations.

The installation process typically involves receiving and inspecting components, precise layout marking on the floor, assembling upright frames, installing beams level by level, and finally, anchoring the entire structure securely.

Even with the best plans, problems can arise. Being aware of these common issues is the first step toward preventing them.

1. Poor Planning and Inadequate Data:

The most fundamental mistake is designing a layout based on guesses or outdated information. Failing to analyze accurate data on inventory profiles, turnover rates, and future growth projections leads to a system that is obsolete from day one.

2. Ignoring Workflow and Traffic Patterns:

Designing the storage blocks without considering how people and equipment will move through the space creates bottlenecks at receiving docks, picking zones, and shipping areas. Aisles that are too narrow for efficient equipment operation are a frequent and costly error.

3. Incorrect Load Calculations:

Every component of a warehouse rack has a specific load capacity. Underestimating the weight of stored goods or improperly distributing weight can lead to overloading beams or frames, significantly increasing the risk of a failure.

4. Substandard Warehouse Rack Installation:

Choosing unqualified personnel for the warehouse racking installation to save money is a false economy. Common installation errors include:

Improper Anchoring: Not using anchors, using the wrong type, or not torquing them to specification.

Unlevel Frames: Even a slight tilt can compromise the entire system's strength and stability.

Missing or Incorrect Safety Locks: Beams must have safety locks to prevent them from being accidentally dislodged by forklift impact.

5. Neglecting Safety Clearances and Codes:

Failing to adhere to local building codes, fire department regulations (e.g., sprinkler head clearances, flue space), and OSHA guidelines can result in fines, forced shutdowns, and invalidated insurance.

6. Lack of Ongoing Maintenance and Damage:

A racking system in warehouse is a dynamic asset that requires regular inspection. Forklift impacts, even minor ones, can compromise structural integrity. Failing to have a formal inspection and repair program leads to the gradual degradation of system safety. Damaged components must be replaced immediately.

7. Choosing the Wrong Rack Type for the Application:

Using a selective rack where a high-density system is needed wastes space. Using a drive-in rack for high-SKU inventory kills productivity. The warehouse racking layout design must match the storage medium to the product.

Your warehouse racking layout design is a strategic investment that pays dividends in efficiency, safety, and scalability for years to come. It requires a meticulous approach that blends data analysis, logistical understanding, and engineering principles. Remember that the design and the warehouse rack installation are two sides of the same coin; a perfect design is worthless if it's executed poorly.

By understanding the different types of warehouse rack systems, adhering to core design principles, partnering with qualified professionals for warehouse racking installation, and vigilantly maintaining the system, you can transform your warehouse from a cost center into a powerful, competitive advantage. Start with a thorough audit of your needs, plan for the future, and never compromise on safety. Your bottom line will thank you for it.

Wechat

Wechat

Whatsapp

Whatsapp